UPDATE: **SOLD** Was $24,950

(08/19/2018) Looks great. Will need a brake job soon. Not many of the Thermador coolers around. Here’s a video of a man talking about one and showing how it works.

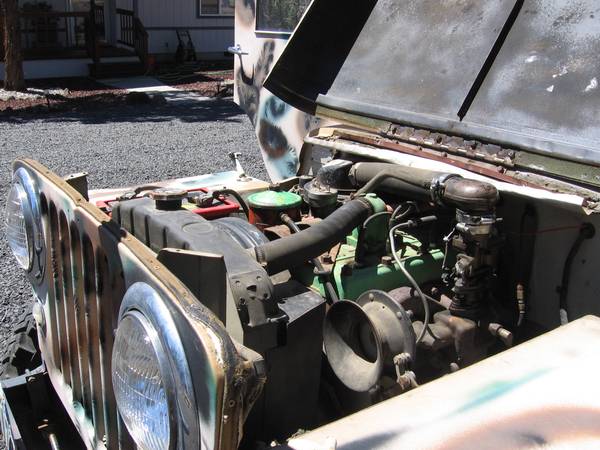

“I am listing my 55 for sale. It was originally purchased in Bakersfield CA by first owner, I am 3rd owner. I did an on body restoration over a 3 year period. Every nut, bolt, wire, washer, etc replaced or restored. Here’s a brief list of what was done

– engine and tranny rebuilt by prior owner (original 6 cylinder engine).

– chrome interior parts and bumper all re-chromed

– new speedo, gauges, wire harness throughout vehicle

– I replaced all 4 tires plus spare, there’s about 3-5k miles on the truck since I owned it

– customer fabricated sun visor

– swamp cooler (very rare)