Today I enjoyed a productive day hunting around the local junkyard. I collected a powerbrake setup, wire plugs, vacuum tubes, manifold connections for the vacuum tubes, gas tank rubber piping, the plastic harness that envelopes the wiring, various knobs, and much more.

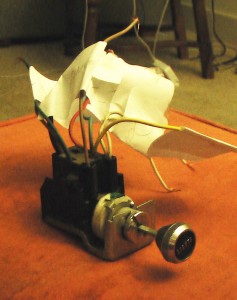

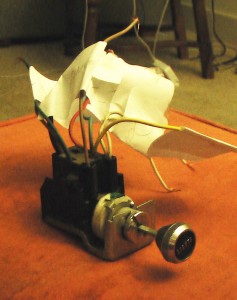

One of the things I never liked about my first jeep was the rather messy way I wired it, including the way I ran the wire around the grille. This time, I have been able to spend more time thinking about how to organize the wiring. You can see the results below. (yeah, that’s the kitchen table — it was getting chilly outside)

As part of the trip to the junkyard, I wanted to find a headlight switch, and some accompanying switches, that I liked. Most of the ones I found were cheap plastic or rubber. After a good deal of searching, I found some real metal knobs on two mid 70s dodge vehicles (truck and a van).

Puzzling through the headlight switch wiring was a bit confusing, because I didn’t have a wiring schematic to follow. At first I tried hooking up the wires in a few different ways to a battery and a voltage tester, but some of the wires still weren’t working. After a good deal of searching, I finally found a schematic that was close enough. I discovered from the schematic that I need to bring in two power sources, one for the headlight power and one for the parking lights/dome light/turn signal power. Using the schematic, I was finally able to label the wires for installation.

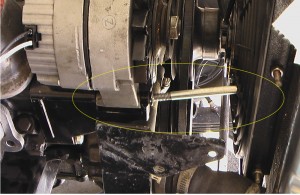

While searching for a wiring schematic, I came across a design for updating the lighting system using some relays. As I understand it, for a variety of reasons, the amount of power that finally gets to the lights, especially under idle conditions, is lower than 12 volts, causing the lights to dim. Using relays and the wiring schematic show should improve the situation. Here’s a discussion about it.

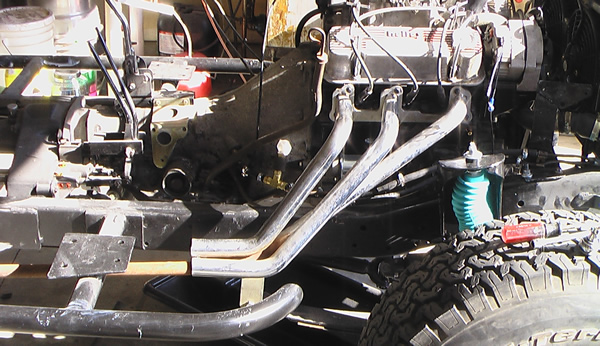

This CJ-5 has got some great extras for jeeping, including posi front and rear, full cage, dual tanks and more.

This CJ-5 has got some great extras for jeeping, including posi front and rear, full cage, dual tanks and more.