A reader just received a 1951 CJ-3A. Since the seats in it weren’t something he wanted, he asked what I had done for seats. I realized I hadn’t really covered the topic, so here’s what I did and why I did it.

A reader just received a 1951 CJ-3A. Since the seats in it weren’t something he wanted, he asked what I had done for seats. I realized I hadn’t really covered the topic, so here’s what I did and why I did it.

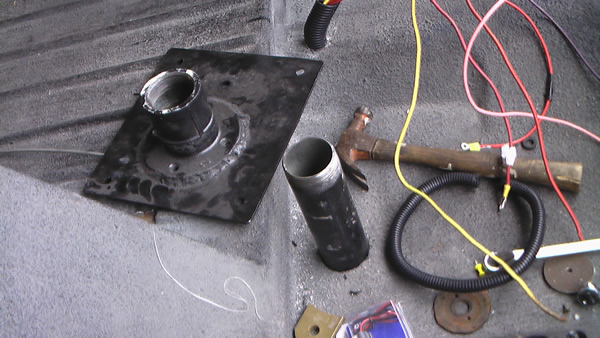

As you probably know, my first jeep was built from an ex fiberglass racing jeep (oh where oh where did those pictures go). From that jeep I used the body, frame, roll cage and seats as the foundation for what became my first jeep (which I called the ‘great escape’). The fiberglass seats were mounted on a 2 1/2″ pipe that was welded to the frame. A hole was cut through the bottom of the body and the pipe stuck through the body (not only did the thickness of the body help keep the pipes from moving, but the pipes held the body in place — a nice synergistic effect). On the upper end of the pipe were threads. Onto those threads a square platform was screwed onto the pipe. The seats were screwed onto the platform. It’s a one size fit’s me approach that works for me and people of similar size. The back of the seats were then bolted to a plate that connected to a bar that was part of the rollcage. So, those seats did not move. They were solid, despite their thin profile.

Because the seats were already there and they seemed to fit me fine, I went ahead and used them as is. As I raced, drove it every day, and used it in the trails, the positioning of the seats was perfect. I felt secure and tight when I raced, I never got uncomfortable during long drives, my back never got sore, and there was enough padding for enduring the trails. For me, those were some of the most perfect driving seats I have ever used.

Continue reading →

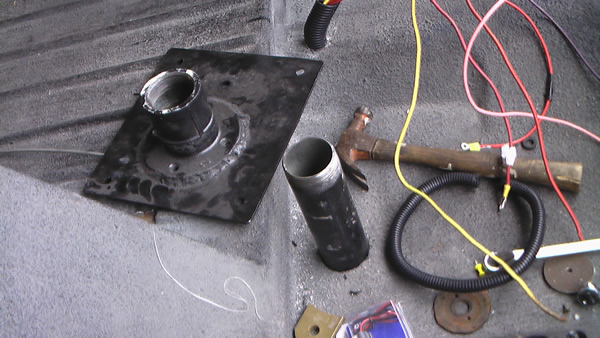

It looks like there’s been a few mods on this CJ-3A, so some type of posi or locker seems possible.

It looks like there’s been a few mods on this CJ-3A, so some type of posi or locker seems possible.