UPDATE: Still Available.

If you are looking for a great, unique Drag race motor (was turning 5s when it was in drag jeep in the early 90s), this might be it.

Steve says this used to be in a drag jeep with a fiberglass parkette CJ-3B body (I’ve only seen one of these – learn more about it here). He told me the name of the jeep, but my short term memory loss seems to have kicked in ….

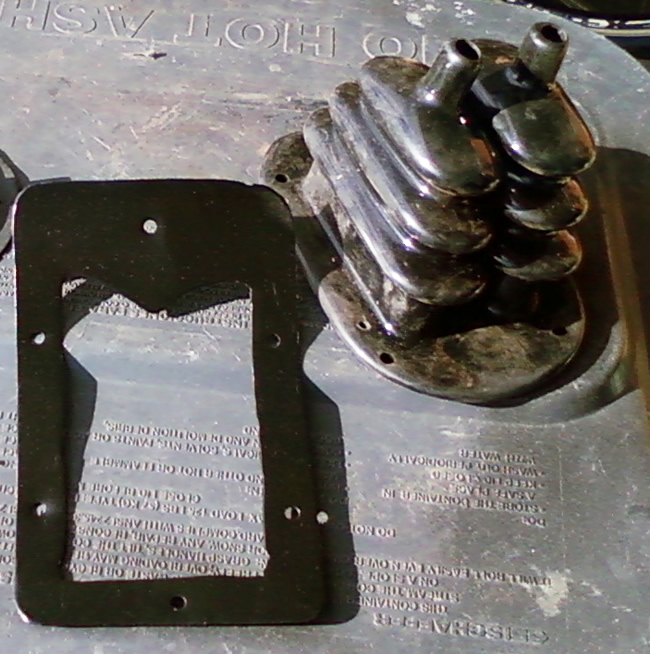

“ Perfect for a rat rod. one of a kind pontiac tempest 4cyl, half a 389 and uses most common 389 parts, this is a high performance engine not stock, it has 10.25 comp ratio, super duty 389/421 330 hp head, balanced and blueprinted, bearings have been inspected and are in good condition, super rare Mallory distributor( stock one will be included, 4bbl intake, has extra parts that will be included (flywheel, water pump, oil pump, rods etc), Blow away the boys in the car club with this one of a kind 60’s era motor, 206 890 6233. call with questions.”

Perfect for a rat rod. one of a kind pontiac tempest 4cyl, half a 389 and uses most common 389 parts, this is a high performance engine not stock, it has 10.25 comp ratio, super duty 389/421 330 hp head, balanced and blueprinted, bearings have been inspected and are in good condition, super rare Mallory distributor( stock one will be included, 4bbl intake, has extra parts that will be included (flywheel, water pump, oil pump, rods etc), Blow away the boys in the car club with this one of a kind 60’s era motor, 206 890 6233. call with questions.”

http://seattle.craigslist.org/see/pts/1476629484.html

1948 WILLYS JEEP,VERY RARE, MUST SELL,”

1948 WILLYS JEEP,VERY RARE, MUST SELL,”

Perfect for a rat rod. one of a kind pontiac tempest 4cyl, half a 389 and uses most common 389 parts, this is a high performance engine not stock, it has 10.25 comp ratio, super duty 389/421 330 hp head, balanced and blueprinted, bearings have been inspected and are in good condition, super rare Mallory distributor( stock one will be included, 4bbl intake, has extra parts that will be included (flywheel, water pump, oil pump, rods etc), Blow away the boys in the car club with this one of a kind 60’s era motor, 206 890 6233. call with questions.”

Perfect for a rat rod. one of a kind pontiac tempest 4cyl, half a 389 and uses most common 389 parts, this is a high performance engine not stock, it has 10.25 comp ratio, super duty 389/421 330 hp head, balanced and blueprinted, bearings have been inspected and are in good condition, super rare Mallory distributor( stock one will be included, 4bbl intake, has extra parts that will be included (flywheel, water pump, oil pump, rods etc), Blow away the boys in the car club with this one of a kind 60’s era motor, 206 890 6233. call with questions.”