Brian has provided a very thorough look at his approach to wiring his CJ-3B. My only wish is that he had written this BEFORE I had wired my Jeep, because I would have created a mockup dash like he did. Many thanks Brian!

Brian writes, I had a major setback in my 3b project when I damaged the valve train on my CPI engine, stopping oil from getting to the lifters. So, I had to swap engines before I could really start my test-drive shake-down period. As part of my swap, I chose to go with the TBI 4.3L V6. What really hurt was that I almost had the wiring complete for a CPI engine, but I knew what worked for the CPI would not work for the TBI engine. This meant a major layout change was in order.

If I had to label this part of my build I would have to call it “The things Painless does not want you to know”, because I feel I was able to save well over $1000.00 by utilizing a free wiring harness I pulled from a Blazer I junked. By working with the stock harness, I was able to use fuel pump relays and other items that help me avoid the nickel and dime effect that can add up to big bucks. I also learned some sort-cuts and where to get OEM parts to help complete the job correctly. So, here’s my adventure ….

LAYING OUT THE WIRING

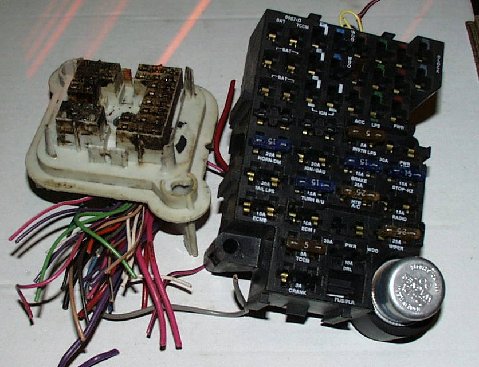

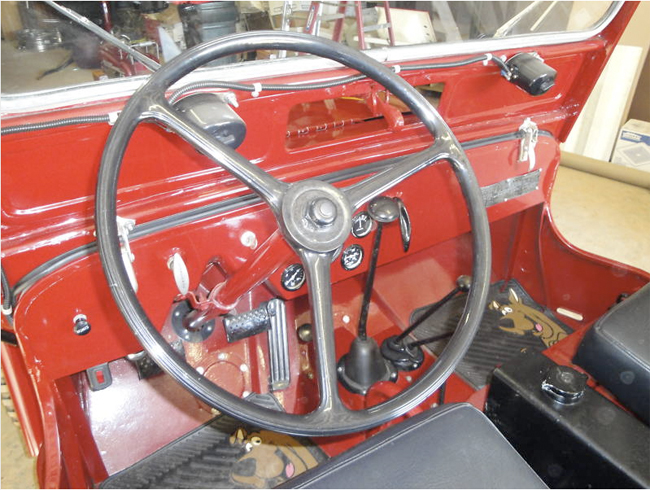

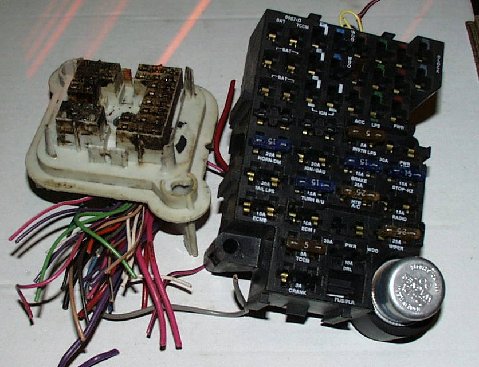

Because the limited amount of space under the dash of my 3b, I had to move things around from the stock location in the Blazer. Fortunately, the harness I salvaged had enough wire to do this. However, trying to rewire and do everything I needed to do underneath the dash wasn’t an option. So, I made a mockup of the dash out of wood that allowed me to easily organize, size and create a well designed electrical layout.

Fuse box firewall bulkhead connector assembly used for mockup.

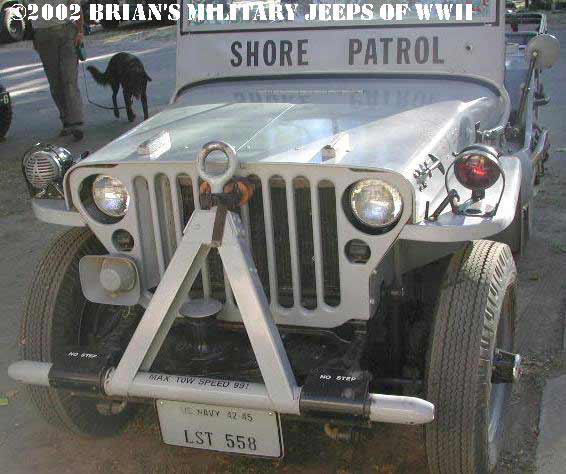

The harness enters the engine space in the same place as the Blazer.Note the valve covers, anyone seeing a nice set of center bolt aluminum valve covers for a 4.3 let me know.

THE CRIMPING TOOL

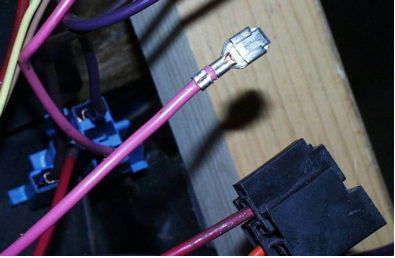

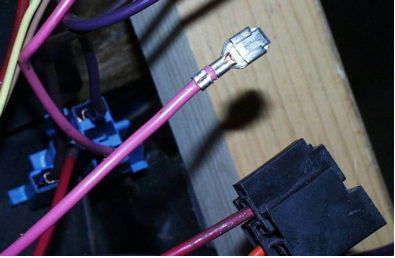

One important goal of mine was to shorten some of the wires and avoid some bird nests of stock wire under the dash. Doing some research I discovered GM uses Packard 56, 58 ,59 and Delphi Metri-pack connectors/terminals that you can buy at PCS Connectors. The advantage to using connectors and terminals “to shorten” is pretty obvious: you eliminate the potential of a splice failure; also, it looks much cleaner.

Having the right tool for wire splicing and terminal connectors is a key. I contacted a small company I was an engineer for and borrowed a ratcheting-crimping tool that you can see below. It took only three tries to get the crimping technique mastered, making my wiring appear professional. (crimping tools from PCS)

Read the entire post by clicking on the link below:

Continue reading →