On Sunday I turned 57. The years seem to be churning by all too quickly! To celebrate my aging, I spent more time removing parts off both the green chassis and the black chassis (no updated pics of that). While spending time thinking and measuring how to use as much of the existing green chassis and black chassis parts as I can, I made an unexpected discovery.

The green chassis is 5 inches wider than the black chassis!. The black chassis is a standard size (29.5″ from inner side to inner side) and seems to be most likely a CJ-3A chassis. The green chassis has the side mounts for the springs and was most likely a DJ-5 chassis as some point. For whatever reason, someone decided the frame rails should be widened, so all the crossmembers were removed but one (which was simply cut and patched using angle iron). The rest of the cross members are all rectangular tubing.

Given the widening, I don’t feel the need to outboard the rear springs at this time (perhaps a winter project). Unfortunately, the wider frame rails mean that I can’t just reuse the sway bar on the back of the black chassis (though I can reuse the mounts). I just need a sway bar that is 5″ wider than the one I have.

I am awaiting the delivery of an adapter so I can try out my new YesWelder plasma cutter to clean up more of the frame and am awaiting delivery of my new MIG Hobart MVP 210 Welder (I have a very very old arc welder that’s a big workhorse on heavy metal, but I wanted something for finer work). I had considered something as cheap as the YesWelder MIG (it is well-rated, but some folks complained about support problems) and something pricier as the Miller Multimatic 215 (which came highly recommended, but may be more than I need right now), but finally decided to get something more in between.

Anyway, here are a few pics of the progress. There’s nothing particularly exciting .. just the drudgery of cutting, grinding, and smoothing areas …

The seat mounting frame (1″x1″) tubing was uneven and not the best system in my opinion, so I cut and grounded the welds flat:

With the seat mount frame gone, you can see the floor base (also 1″x1″ square tube). It’s not welded level (ugh), so it will likely go away as well.

The side rails needed to be replaced as they were built for the narrower body, so off they came. I also plan to do a side bar similar to the way the other frame is done (more on that later).

Also gone are the mud flaps on the back (racing requirement), as they were welded onto the inside of the rear tubes (ugh). I will cover the rear tube with plates to hide the parts welded inside, then will cut off and mount the flap system used on the other frame, which is a long tube welded under the rear bumper with flap mounts that are bolted onto the tube (again, more on that later).

We plan to have a garage/estate sale this weekend, so work will slow for a few days. At least I will finally be able to get rid of a bunch of junk that has filled the shop. As Ann has been finalizing stuff in the house, more items have ended up in the shop, so I will be happy to have this stuff gone and have more room to work.

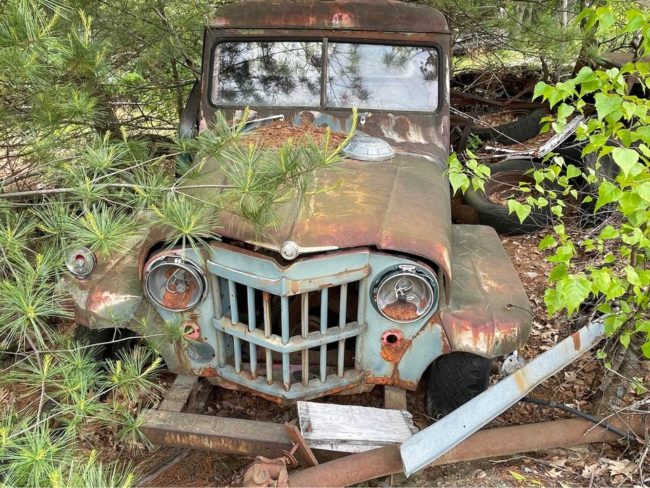

Finally, I am awaiting a new fuel pump for Patterson (which has taken more than 2 weeks to get here). Once that is here, I will test things out once more, then put Patterson up for sale (essentially trading up for a different jeep, but I will announce that later).