With winter settling into Alaska, Paul has returned to continue work on his Stainless M-38 (and a matching stainless trailer). I believe this is the 28th year of the project? Thanks for sharing Paul!

Knarley Rolls, Paul’s M-38. The spare with its cover is attached to the back of the jeep.

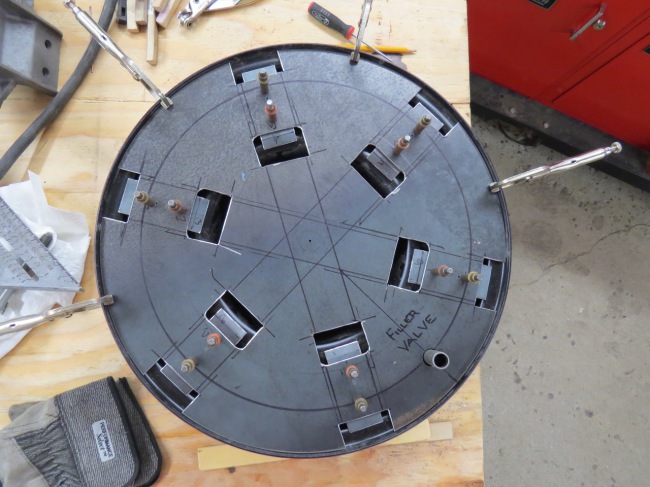

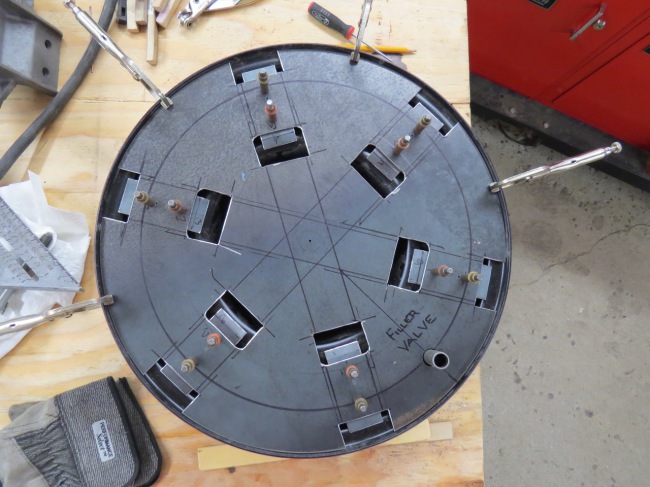

The black steel wheel in the photo below is one of 8 new wheels I purchased for the Willys (4 and a spare) and the M100 trailer (2 and a spare) so I need to modify these wheels to accept the stainless wheel discs I previously made. Each wheel will have 6 metal tabs (evenly spaced) welded to the outer face of the wheel with the tabs running from the outer bead flange to the raised inner ring around the lug nut area and each tab will have two nuts welded to the inner surface. These nuts will line up with holes drilled thru the stainless wheel discs to accept the wheel disc attach hardware and the tabs will provide additional support to hold the wheel discs while driving.

The black rim is to the right covered by a template. The other parts are trailer pieces from the disassembly of his trailer.

My original plan was to have only one nut per tab (so the wheel disc would be held on with six machine screws) but it’s much easier to weld two nuts to each tab while I’m making the parts than to have to add additional nuts and attach screws after the wheels have been powder coated just in case the discs wobble during rotation. I’ll try the 6 attach screws per wheel first and if the wheel discs stay smooth during driving I’ll leave the extra 6 nuts empty. If the disc shows any sign of instability while driving I’ll use all 12 screws to attach the disc for extra support.

Continue reading →