I am typing this while recovering from a wasp sting that caused my right hand to swell (it’s been an odd health year for me!), which sent us to the local doc-in-a-box to get some steroids, which in turn helped reduce the swelling (after 24 hours). I’ve never had a reaction to a stinger like that, so it’s a bit of a surprise!

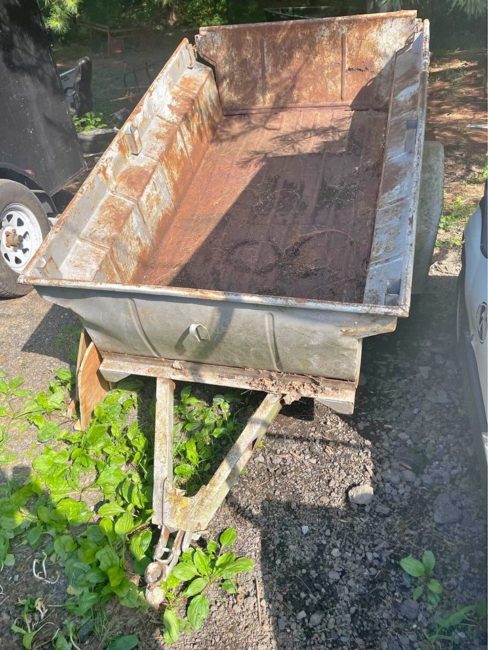

Last week I finalized the body mounts. Hinges attach the body to the back of the frame in two places. Two single bolts with large washers hold the mid section of the body to a plate on the roll bar. And, two bolts through angled aluminum hold the bottom front portion of the cowl to an angle piece on either side of the body. On the upper portion of the sides of the cowl some rubber taped to the inside of a bracket keep the cowl from shifting back and forth.

The front clip is proving a bigger challenge than the body. First, I had to cut out part of the the driver’s rear-side portion of the front clip because it was too narrow and hit the side of the body. So, I am creating a form and will lay some new glass down (along with patching a few other places).

Then, once the hood fits properly, I will have have to build special mounts for the front clip. The goal is to reduce the stress on the hood, as these things are often mounted with quick release setups that allow the body to flex, making it more prone to breaking and cracking and/or rubbing on the body.

Here are a few pics:

I decided to to throw a couple blocks (made from some of my grandfather’s wood) onto the hood that are a nod to the original hood blocks, but will also tie in a frame underneath the hood to help support and mount the front of the hood.

You can see part of where the hood is cut out. The form will allow for the new portion of the hood also down fender to flare outward more (or that’s the plan).