Take it away Paul ….

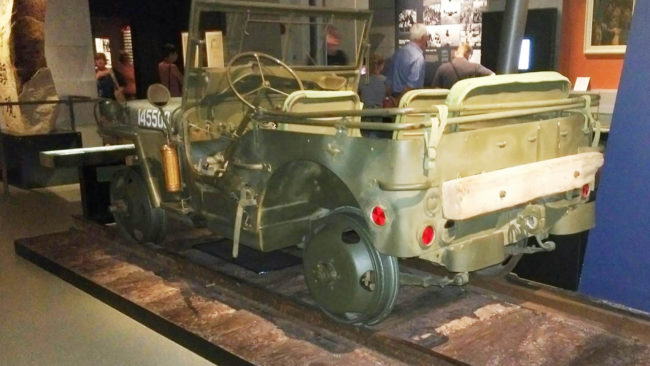

For the past couple of weeks I’ve been disassembling, cleaning, bead blasting and repairing parts for the little Willys and the M100 trailer so they would be ready to be powder coated. I still need to install new wheel studs in the hub flanges along with pressing in the new bearing races but that task should be finished tomorrow. The driveshafts need one to be shortened and one to be lengthened before they’ll go to the powder coater but progress is being made.

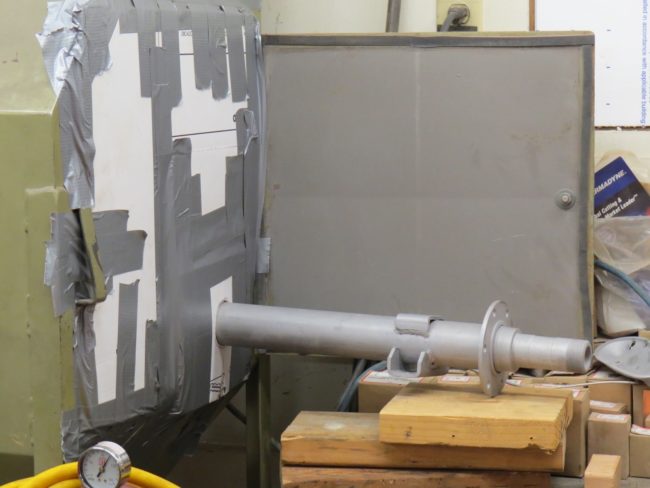

The blast cabinet is 48 inches wide overall and the axle is slightly over 53 inches long so I had a bit of a problem fitting the axle in the blaster and still having room to clean the rusty steel. My solution was to leave the side door open and block the opening with multiple layers of cardboard (taped to the cabinet) with a hole cut slightly larger in diameter than the brake backing plate mount on the axle to allow movement of the axle during blasting.

Before I began blasting I added two more pieces of cardboard (cut to fit snug around the axle tube) to cover the larger hole in the cardboard end cover. With this cardboard and duct tape combination I was able to carefully blast two thirds of the axle without filling the air with glass bead dust. Once the axle section in the cabinet was clean I removed the axle, turned it end for end and inserted the rusty end into the cabinet to finish cleaning the metal. This photo shows the low tech cardboard and cheap duct tape alteration of the blast cabinet so the axle blasting could begin.

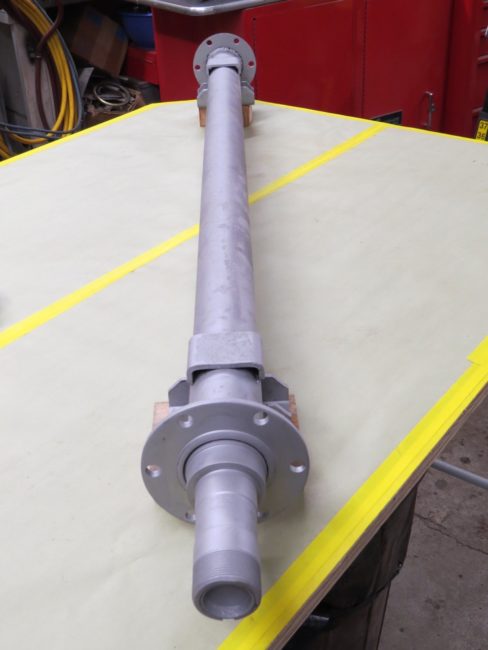

The air compressor was blowing lots of air but the glass beads still had to work pretty hard to clean all of the rust off this 65 year old axle. The metal is lightly pitted (especially on the forward side) but I don’t feel the original strength of the axle has been weakened in any way. I checked the axle and the spindles with a straight edge and a level every 90 degrees of rotation to see if it was bent but the axle tube and the spindles are straight.

Here’s the axle just out of the blast cabinet ready to visit the powder coaters where it will receive a nice satin black coating.