On Tuesday afternoon, Patterson sprang to life with it’s new transplant!

We started Tuesday morning working through the wiring. I asked Ann to rewire the low-beam/high-beam floor switch, since much of the fabric had fallen away. That led to rewiring more of the harness than expected, which in turn delayed messing with the engine.

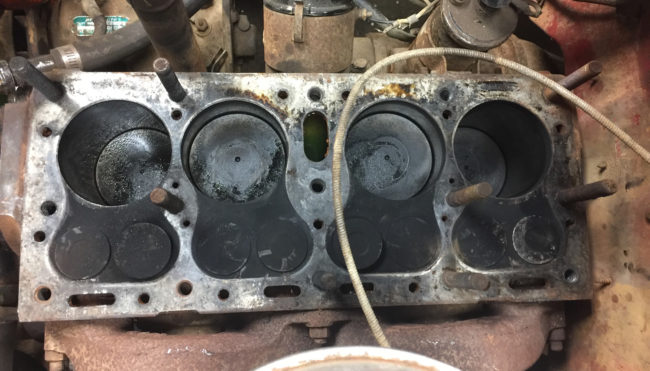

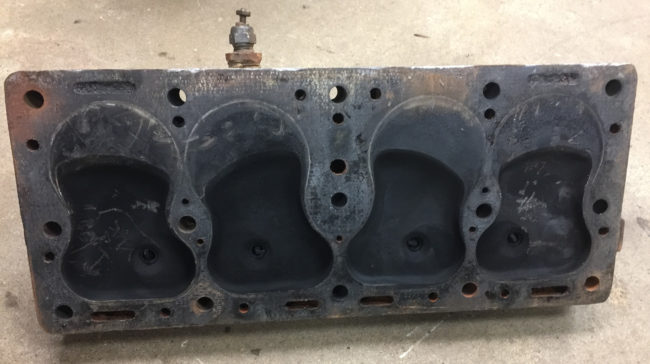

Once I could focus on the engine, the first thing I did was swap distributers, as Patterson’s engine had newer internals (and I knew for sure it worked). When installed, I tried starting the engine a few times, but didn’t have success. So, I rotated the distributor wires 90 degrees. When that didn’t work, I rotated them another 90. When that didn’t work, I rotated them another 90. That’s when I got the engine to fire, but not run. At that point I began rotating it a few degrees, then cranking the engine, then rotating again, so I could get a feel for which position seemed to fire the best. But, after trying this a few times, we still didn’t get it to run.

At that point, Ann suggested we try different spark plugs. I’d forgotten I hadn’t installed the ones that had been on Patterson (still attached to the head). So, we pulled them, checked the gaps, then installed them in the “new” engine. We got it to fire again, but then, mysteriously, it stopped firing no matter where the distributer was located. That was puzzling. About that time, ann noticed some heat at the generator. I suspect the regular got stuck, causing the battery to discharge into the generator, creating heat (at least that’s what I determined later of after doing some reading). So, I pulled the battery cable and let the system cool.

Once it was cool, I rotated the distrbutor back to teh position where it had fired the best, then climbed into Patterson to start the jeep, simultaneously working the choke and gas pedal. Sure enough, Patterson just needed some physical presence in the driver’s seat, because he started right up. At that point, I climbed out and played with the distributor to locate the sweetest sounding spot. (see the video on Facebook … I can’t seem to make it appear on eWillys … it lacks a muffler, so it’s a little noisy).

So, Patterson runs again. But, we discovered the temp gauge and oil gauges are not working, so those will need some attention. Unfortunately, we had to return to Pasco last night, because Ann has a doc appointment Wednesday. I accompanied her back to Pasco, as I have some updating to do to the website and need to organize the sale of some Alaska Or Rust t-shirts. More on that Thursday morning. We plan to be back in Renton early next week. My mother has knee surgery scheduled for the 5th, so we need to be around to help out.

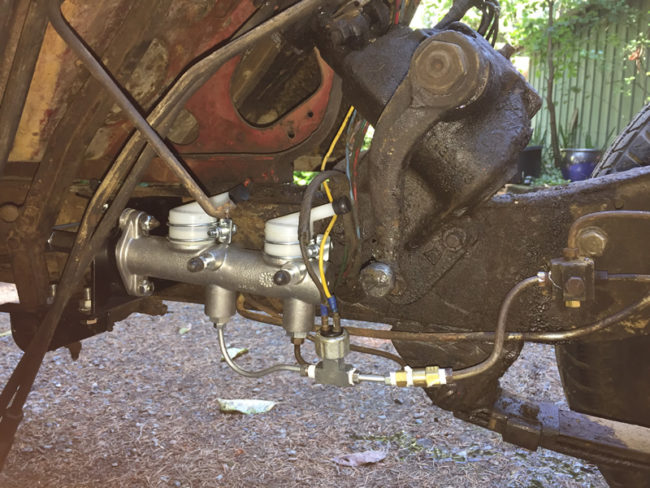

And, some of the blasted parts … clutch linkages, pedal levers, column shift parts, and more:

And, some of the blasted parts … clutch linkages, pedal levers, column shift parts, and more:

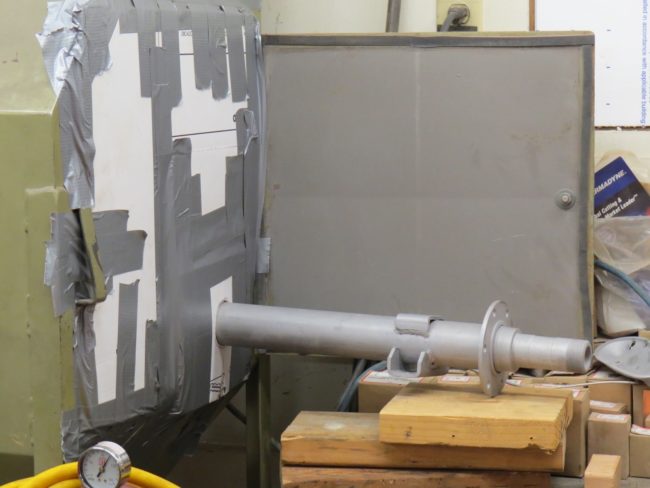

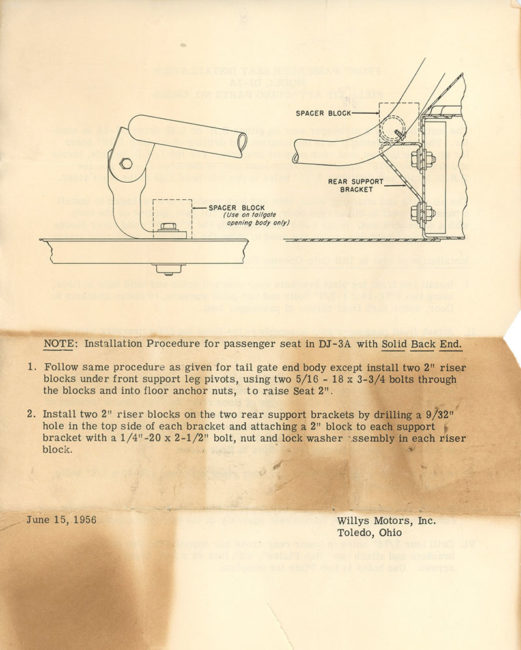

You can see there’s a gap between the board and the back.

You can see there’s a gap between the board and the back.