It was a sunny (finally), but cold day yesterday. So, Colter and I took a quick drive into the hills to smell the coming spring. Here are a couple snapshots.

Biscuit Research Archives

Pounced: Biscuit Finally Has Its Name

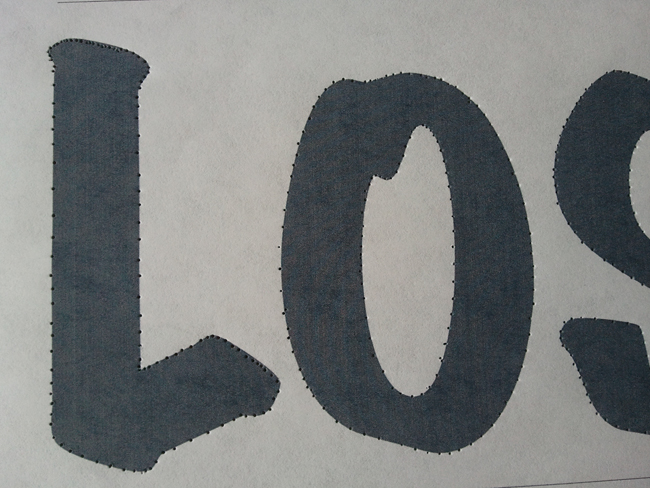

It was sometime around mid-summer of last year (maybe earlier) when I started the project to place ‘Lost Biscuit’ on the hood of my jeep. It took a little longer than expected, but I finally did it.

First I had to decide which font to use. Fortunately, I got some very helpful input along the way from Dexter (thanks) and eventually decided upon the Marker Felt font. Okay, that was pretty easy.

Now, how to get the name on the hood. After hmming and haaaing over how I wanted to attach the name (hand drawn, stickers, stencils, pay someone else … ), I finally decided I would do it myself using paint. But, I knew my freehand drawing and painting skills froze around the 2nd grade, so this wasn’t something I could improvise. Since I had no immediate solutions, I decided to put the project on hold (which explains the delay).

One day this past December I was watching American Restoration on the History Channel. The American Restoration show is a spinoff of sorts from the Pawn Stars show and follows various restoration projects from Ricks Restoration out of Las Vegas. In one of the episodes, called Buttered Up (you can view it here), Rick restores an old popcorn machine.

To repaint the front of the popcorn machine, the painter used a technique that dates back centuries called pouncing. Pouncing? My ears perked up!

Pouncing? Never heard of that. As usual, my computer was on my lap so I instantly googled pouncing. I learned,

Pouncing is where pounce — loose graphite or charcoal — is rubbed through a series of small holes punched in a paper pattern to transfer the design to an item to be decorated

Well, I thought that would work for Biscuit’s name. After some more research, I found out that quilters use pouncing for some stitch patterns. So, the next day I hit some quilt stores. As you can imagine, the conversation went something like this,

“Hi, I’m here because I want to paint a name on my jeep,” says I.

Blank stare from cashier, “what do you need?”

“I need stuff for pouncing” says I, remembering now that I probably had not shaved, maybe, not even showered, and most likely wasn’t quite dressed like customers they normally help (however, to my credit, I didn’t have on my garage jeans).

Another blank stare, “you want to do what?” I think she even had her finger ready to dial ‘9’ (and then ‘1’ ‘1’)

It turns out, not everyone knows what pouncing is, even at the quilt stores. Eventually, after visiting a couple quilt stores, I found what I needed (you will see my pouncing supplies in a picture below).

Here’s the synopsis of this project.

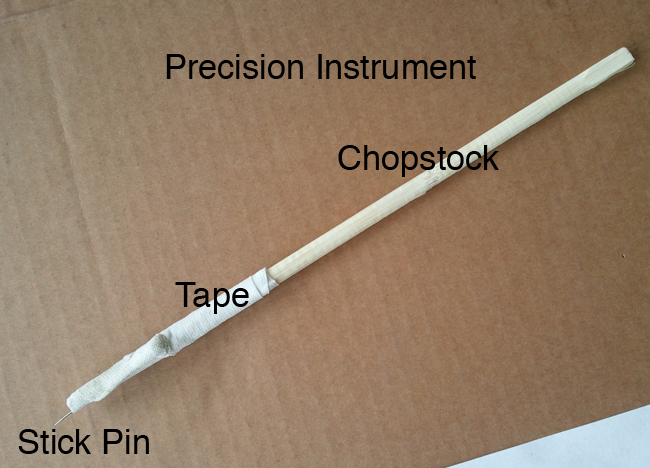

1. Design and Print the template. Then, since I didn’t have a good awl, I created my own awl out of tape, a chopstick and a long push pin.

2. Next, I attached the template to a piece of cardboard. Then, I poked holes around the outer edge of all the letters.

3. With the letters outlined, I tested out the template on different materials to make sure it worked. It turns out pouncing is pretty easy!

4. Selecting paint was the next step. So, I visited my local art supply store and explained to them what I wanted. They directed me to an Acrylic Titanium White Tube from Windsor Newton. Along with the paint, they also suggested an acrylic spray on sealer and finisher from Americana. I took the paint home and tested it on different materials. At first, I didn’t like it, because it wasn’t as smooth as the typical oil based house paint I had expected. Instead, it had texture like a canvas artist would want. But then, after staring at it a bit, I warmed to the texture, because it gave the name a hand generated feel.

5. Yesterday, with the weather a little warmer, it was time to paint the name. I got out my template, my paint, and my pouncing supplies. I taped the template to the hood and prepared to pounce.

Over the course of my tests, the technique I found most successful for pouncing was not tapping the pouncer, but rather dragging it slowly across the holes. This kept the paper from popping up and blurring the dots underneath.

The pouncing equipment consists of a pouncer with a ‘handle’ on one side and a soft side on the other. There’s also a plastic container that can hold pounce. Lastly, there is the white chalk.

6. Now it’s time to paint. I put three coats on each side. This image was taken after the first coat.

This is after three coats.

There is still some small edges that need cleaning up. Once I do that, I’ll spray it and hopefully that will protect it!

Some Days are Harder than Others ….

The plan was simple, fool proof, and, best of all, idiot proof. But, alas, not Dave proof. The goal, attach my new ‘ewillys’ stickers to plates and attach them to the sides of Biscuit.

Step One: Have stickers made — CHECK.

Step Two: Cut and shape Ovals out of a street sign (note: not snagged from the subdivision down the street, but from a metal yard) — CHECK.

Step Three: Drill plates for mounting holes — CHECK.

Step Four: Attach stickers — FAIL … well, they are ‘stuck on’, but they have bubbles. That’s $50 down the drain — do over time.

See, had I made step Four “Check the internet on mounting vinyl stickers”, I would have been ok. But nooooooo, instead, I cleaned the plates with a degreaser (should have used soap and water), wiped them dry, and then stuck the stickers (should have sprayed some water and a little soap onto the plate and then squeegeed the sticker onto the plate).

Ok, lesson learned. So, I bolted the stickered plates onto Biscuit, just for kicks. I stepped back and took one look and knew I had screwed up, again — twice in one day! See, I thought that hiding the allen bolts, which are black, along the black lines of the ewillys’ script would hide them. But this didn’t happen. Instead, they disrupt the eye as you read the logo, both close up and from up to 20ft away. So, now I’m really ticked. So I mounted the plates to teach myself a lesson — don’t presume to know what you don’t, check the interet first!

When I cool down, I’ll get some new stickers printed, properly attach the stickers, and widen the bolts left and right.

Below is a blurry pic of the attached sticker. I’ll replace it with a better one tomorrow …. Hopefully, I’ll keep someone from making the same mistake 🙂

Tubing in a Tubeless World

I admit that sometimes I’m entirely clueless. Today was a perfect example, for today I got my Desert Dogs mounted onto a 2nd set of Hurricane Rims that have been holding down the garage floor for more than two years.

I admit that sometimes I’m entirely clueless. Today was a perfect example, for today I got my Desert Dogs mounted onto a 2nd set of Hurricane Rims that have been holding down the garage floor for more than two years.

The last time I got a set of offroad tires mounted on a set of rims was 27 years ago. Those too were desert dogs. I had inner tubes added to the tires so that the air pressure could be dropped to 10 – 15 lbs when jeeping; using inner tubes was a very normal thing to do.

So, now you will understand that when I pulled up to Les Schwab Tires (btw, Les Schwab, the company founder, was an early fan and seller of the Desert Dogs) and told the guy at the counter what I wanted to do, I didn’t think much of it. He walks out, looks at the rims, looks at the tires, and tells me he doesn’t think the tires will actually fit the rims. Frankly, he was looking at me like I just dropped in from planet Mars. Fortunately, I’m used to people looking at me like that. I told him that Les himself would have mounted Dogs to rims similar to what I had. He took it all in and seemed to think that maybe my request was possible. So, I asked him for an estimate to mount the tires and add inner tubes.

He gave me an estimate ($91 to mount and balance them) and said he didn’t know if he could get some inner tubes, because running inner tubes on tires like that would cause them to heat up and explode (the inner tube explode that is). Now it was my turn to look at him like he was from Mars.

However, to his credit, he was courteous the entire time and spent extra time attempting to locate inner tubes, finally finding four tubes at a cost of $38 …. that’s $38 a piece. After some quick addition I concluded that would cost me almost $160 just for tubes!! I told him thanks, I would see what else I could find for inner tubes.

So, I left, went home, and hopped on my beloved internet, hoping I could find a better price. After a half our of searching the internet and finding nothing, I had an idea. I would call Bucks, a local 4×4 shop, to see what they used. They said they rarely use inner tubes. The last time they used them, they got the tubes from Commercial Tire.

It turns out, in a world of tubeless tires, the use of tubes, once standard practice, has evaporated. Worse, no one told me!

My next step was to call Commercial Tire and see what they could do. The guy on the phone was helpful and said tubes would probably cost about $23 for my tire size, however I’d need to check the stem size of the rim as the tube price he was quoting was for a tube with a thick stem.

I figured I had nothing to lose, so I drove over to Commercial Tire and asked for some tubes. They looked at my stem size and determined I needed a rare inner tube. Several employees started making calls and one finally found four tubes at a warehouse somewhere and that was all they could find. The price would be $35 a piece.

I still thought that was crazily high, so asked them to just give me a quote on mounting the tires. They said they wouldn’t mount them because they were older than 6 years. So, my trip to Commercial Tire was a waste of time; and it confirmed that the world of tires had changed while I had been away from jeeps.

I left Commercial Tire and made the decision that I would mount the tires without tubes and give that a try. Since Les Schwab was willing to mount the tires, I decided to just take the tires back to them and get them mounted. Then, I took the mounted tires home and put them on the jeep.

So, maybe putting 18 year old shoes on Biscuit isn’t the smartest decision, but I couldn’t resist. They probably have 5000 miles of road wear left, maybe a little more. However, I had to do this to complete my image of what Biscuit would be: a fiberglass flattie with an old school look.

Here are a couple images of the new, old tires. I do prefer the pure aluminum color of the other rims, rather than having the black within the splines. So, I plan to polish the rims at some future point and take off that black.

Oldies but Goodies – Desert Dog Tires

The main reason for my trip to Seattle this weekend was to pick up a set of Forumla Desert Dog tires from Mitch with some good tread still left that I can use as offroad tires. I have four more hurricane rims just aching for these tires, so I can’t wait to get them mounted. This should really make Biscuit ready for summertime explorations. Thanks Mitch!

Biscuit’s Gas Pedal Design

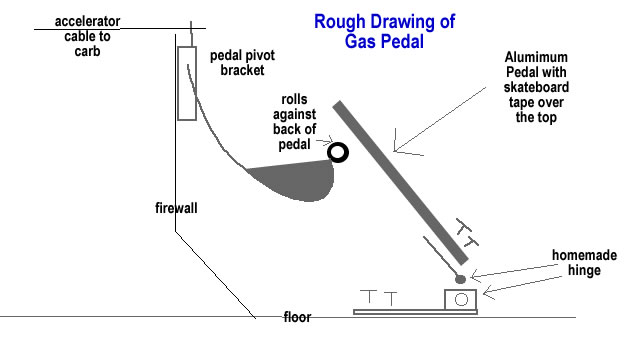

When I built my first jeep, I used the gas pedal from a CJ-5. It was fine for driving around on flat smooth roads, but when I hit a bump, my foot tended to flop against it, which meant I would accelerate unintentionally. It was just too sensitive an arrangement (dad used a CJ-5 pedal in his CJ too and had the same problem).

Eventually, I found a solution to the pedal problem. However, it took a bad day of racing to get there ….

Early in the Spring of 1985 I was at a PNW race competing in a team relay event somewhere north of Everett, Wa. I remember the conditions clearly: It was cold, it was damp, and it was rainy.

Jim, Tim, and Steve Carter and I teamed up for the relay event. Between us we had three jeeps (my jeep, Otis and Priority I — or maybe II or III — I can’t keep track of all the Priority versions …).

It seems to me we advanced to the first round with no issues. However, during the second round, things went awry. Frankly, the precise details of how the rest of the race played out have faded with time. What I do remember is this; First, my front driveline broke as I made my way around the course. Then, when driving Priority, I broke its front drive line. Finally, when driving Otis, I was trying to drive carefully as I REALLY, REALLY didn’t want to break another driveline. At one point I got a little stuck (it was really muddy) and thought I had broke it (ugh!). Fortunately I didn’t … I was perfectly happy to stop racing that day (we got eliminated in the 3rd round I think).

I tell this story, because while racing Otis, I noticed that my foot didn’t bounce and nor did the pedal no matter what bumps I encountered. It was solid, yet the pedal depressed when necessary.

Later in the day, after racing, I looked at Otis’ pedal and discovered Jim had set it up so that the there was a roller behind the pedal. While more complicated than the normal pedal, it really improved the ability to keep driving and accelerating smoothly over bumps.

So, I implemented that in my first build and loved the results. I had hoped to implement the same thing in Biscuit using a classic foot shaped pedal like the Moon Aluminum Pedal. However, I couldn’t justify the cost (read here that my budget was getting tight), so I implemented what I call Version 1.0 of the pedal.

Using some aluminum plate I already had, I drew the shape of my foot onto the plate, cut it out, and then shaped it with my grinder. Then, I went down to a locate skateboard shop and purchased some skateboard covering (sandpaper-like on the front and sticky on the back). I cut the covering into the shape of the foot and stuck it onto the plate. It isn’t beautiful, but it works well.

I’d like to clean up some of the rough edges in Version 2.0. Below are some pics and a highly(?) technical schematic.

BTW, that race was the last day I broke a driveline. I’ve never had a problem since.

Always Double Check Your Lug Nuts …

It all seemed simple enough. I’d pull off the front, driver’s side tire, pull off the front brake drum, adjust the brakes (The front right was pulling some on braking, so I needed to adjust the front left), and put everything back together … easy enough, yes?

Well, that was last night. This morning, I hopped in the jeep and drove down to the local gas station to get some gas, before heading to the local home/garden shop (Zamzow’s).

As I exited the station, my pedal suddenly drops to the floor. Hmm .. not good. I jump out, lift the hood, and, sure enough my accelerator cable connector had come loose. I re-attached the cable and drove back home to more permanently fix the solution.

So, I’m back on the road, heading to Zamzows again. Life is good. I drive about 2 miles and I start hearing a tinging; “an odd sound,” I think to myself …. I listen more closely; “That is coming from the front left side.”

And then it hit me, “had I tightened the lug nuts from my brake work the night before?” Crap, I couldn’t remember.

At just that moment, when the grip of dread descended upon me that I might have forgotten to tighten the nuts, I was looking down at the driver’s tire, driving about 35 mph, when a silver bullet shot from the wheel and landed in the grass divider (never did find it). Holy shit! That was a lug nut! I pulled over into the median (it’s a rural road with a grass median) and checked out the situation.

After doing some accounting (yes, that MBA of mine really came in handy about now), I concluded the situation was not good. 1 lug nut missing. 2 lug nuts loose. 2 lug nuts holding on the rim. 0 tools … and 1 idiot standing there (yes, that would be me).

What to do? Head back home very slowly. Every 1/4 mile or so I stopped, jumped out, hand tightened the lug nuts, got back in, and kept going. Drive another 1/4 mile & repeat. You get the idea!

I finally did make it home, tightened everything back up, PACKED MY TOOLS, and took off again. No more problems the rest of the day … whew!

However, to add insult to injury, my adjustments still didn’t fix the pull to the right I have! Just know that I won’t be forgetting to double check my lug nuts in the future!!

Me and Dad Circa 1982 near Milk Lake, Wa

From the scrapbook archives comes this image of Dad and I readying ourselves for another day of jeeping. I believe this was in 1982 (which would make me 17 and dad 49). I remember the overnight at Milk Lake because we slept in the lean-to (see the blue tarp in the background), which was the first time I can remember doing that.

In the pics you can see the aluminum storage units with some supplies in them. Dad built those from Boeing Surplus leftovers, rivets and a rivet gun. They were light, easy to pack, and stored over the wheel wells, between the roll cage bars, so they were accessible on the trail as well.

Biscuit’s Back Seat Project

With the kids coming up to visit, I wanted to add a backseat that would allow more than two people to go jeeping. My goal was to combine the seat with a new tire carrier and have the entire unit easily installed and removed. This current setup doesn’t allow for a tail gate; however, I don’t care about that right now. In fact, I could create a back that is permanent with this unit at some later time if I wanted a tailgate.

So, here are some pics of the process:

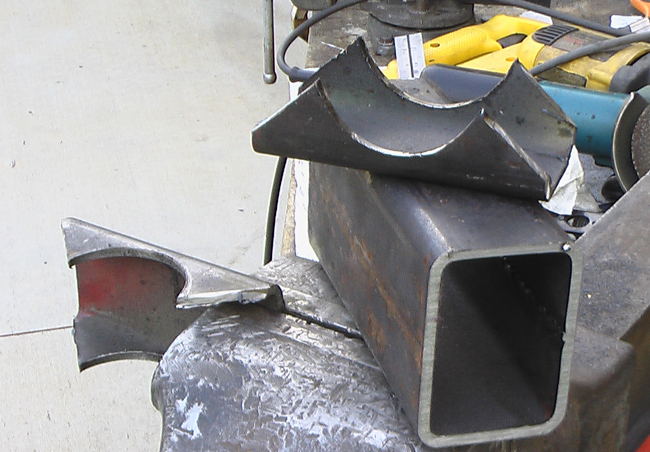

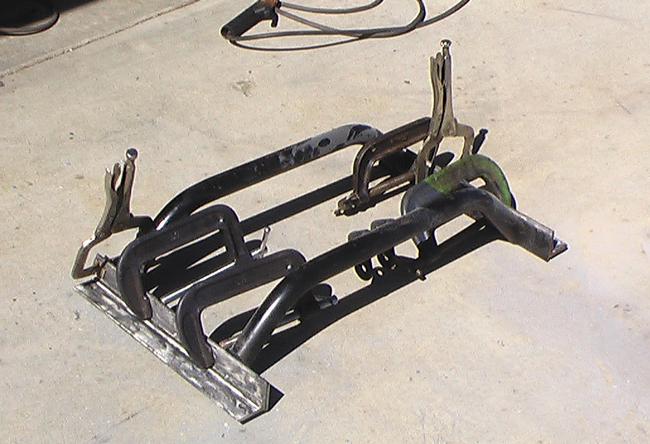

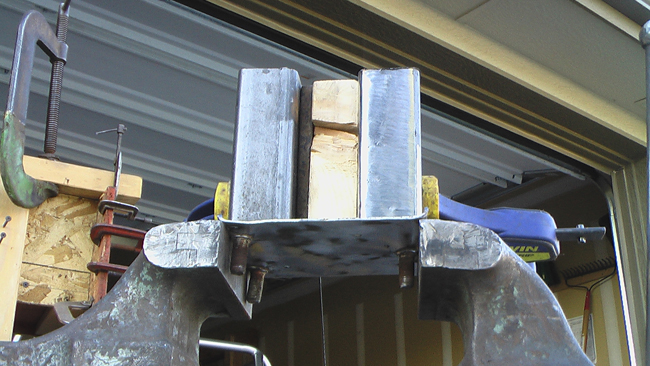

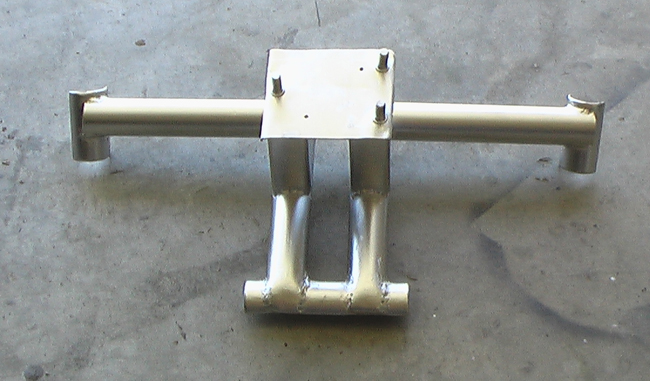

I started with a couple brackets that bolted to each side of the rear portion of the roll cage that were connected by a heavy piece of angle iron (I have lots of heavy angle iron).

Next I bent a loop from some roll bar tube and then welded it to the angle iron (you can see that I needed to trim a bit from the bottom of the loop). Then, I added a left and right arm that I attached to half-tubes which I clamped to the roll bar. The loop leans backwards at the same angle as the front loop angle leans backwards.

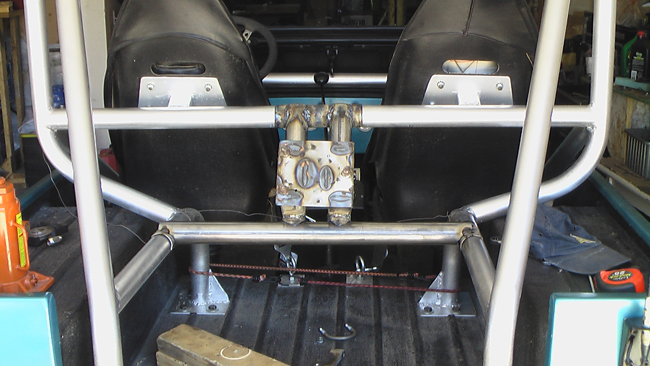

The next step was to add an attachment for the rear tire carrier. I welded a piece of tubing to the top of the loop and a bent piece of tubing to the angle iron. In between, I welded a piece of rectangular tubing.

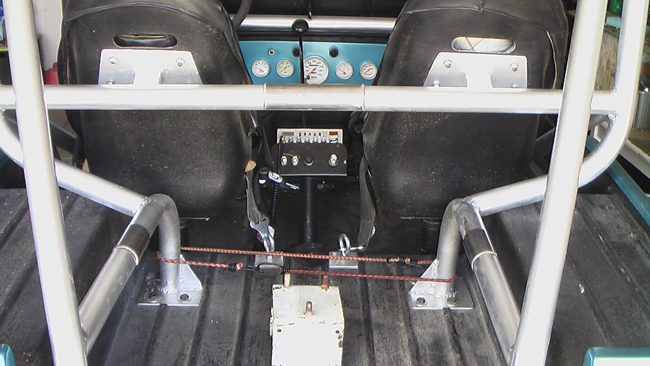

Then, I added a platform for the bottom of the seat.

After creating a template for the plate that will hold the spare tire, I cutout a piece of heavy metal, drilled three holes, inserted the studs, and welded them in place. Then, I welded the plate onto the until. Here, Karson is doing some spray painting.

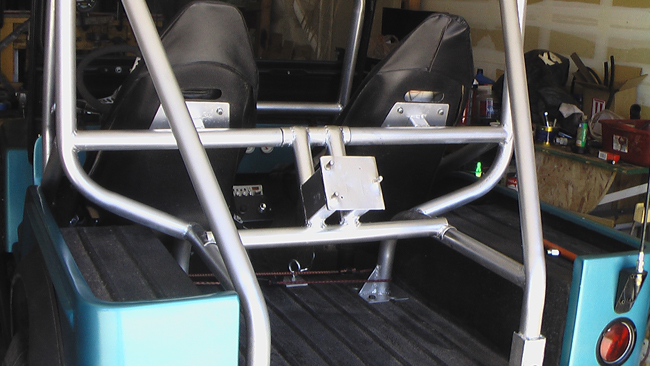

Next, I added a strip of metal across the back loop so I could bolt on the back of the seat (made from wood). The bottom is also wood and bolts in place. Both still need to be padded. The final pics below show the entire unit in place (though I have since painted the wood black and the strip across the back the color of the tubing). This is nothing fancy and, though not as wide as I’d like, will meet my needs for now. And, we tested it out today and the kids love riding back there 🙂

Some Updates …

For the Fourth of July, I celebrated by heading back to the formerly snow bound roads near Boise’ only ski area, Bogus Basin. As you can see in this pic, the snow is gone (see snow pics here), the mountains are now in bloom, and more progress was made. More on that tomorrow ….

A 1950 CJ-3A: Today, Darrel had to talk to me. So he stopped next to me, while I waited at a stop light, rolled down his window, and started asking me questions — what year was my jeep, who did my roll cage, and more …

Now, I had no idea who Darrel was. However, in the time it took for the stop light to finally change colors, Darrel had explained through his passenger side window that he A) liked what I had built, B) had a 1950 CJ-3A, C) wanted his jeep rebuilt for his daughter, D) had his jeep nearby, and E) wanted me to follow him there. If I learned that much at a stop light, I wondered how much I would learn about him once we stopped to see his jeep.

True to his word, he lived very close and had a 1950 CJ-3A that needed some work — hadn’t been run in 15 years. It had a V-8 conversion, solid body, rotted top and plenty of potential. And, to my surprise, based on my jeep, he asked me to do the work (and will pay me). I don’t have pics of this just yet. I’ll share more about this if we go forward with the project.

Brian wrote to me late last week to share a sad tale. As a part of the continued testing with his new build, he learned the hard way what happens if the oil in the front pumpkin housing gets too low AND the 4wd somehow gets accidentally shifted into gear (how that happened is still a mystery to him). The result: his front pinion started freezing up, resulting in some ugly sounds and a twisted driveline. See the pics to the right.

The good news is that everything else continues to behave well.

Zen and the Art of Geometry

I blame my mother.

Had she not very kindly given me some cash to do ‘whatever’ I wanted for my birthday, I wouldn’t have gone to the Jungle Jims on my birthday. I wouldn’t have pulled those springs off the truck. I wouldn’t have installed the springs, that lead to the vibrations, that drove me crazy all month, that forced me to pull apart Biscuit’s entire rear end and redo everything – spring pads, shock mounts, and the transmission undercarriage.

So, a simple 1.5″ lift thoroughly disrupted my entire month. How’d this happen?

I blame the recent emergence of geometry. You see, 20+ years ago geometry didn’t exist. Or maybe it did, but somehow, in someway, my 1st jeep was enveloped in a geometrically-free zen-like zone where geometry didn’t apply, because I never had the problems I encountered this month, despite the fact I set up everything else nearly the same.

What am I rattling on about? I’m talking driveline geometry 101. Unfortunately, I was busy the day they held that class. So, I set up my driveline in the same manner I did my old one: My driveline angled straight out from my pumpkin (with the pumpkin angled at the transfercase like the way it should be done when a CV joint is used), with the only angle at the transfercase. I probably put 10,000 miles on my last jeep without issue. So, why would I do anything different with the new jeep?

Well, everything worked on Biscuit, until I put the 1.5″ lift. But, that little change caused the angles to change enough that the driveline was vibrating my socks off at certain speeds, which is a pretty good trick since I normally wear shoes while driving. So, as I detailed a couple weeks ago, I thought I had solved the issue by using an angle shim to adjust the angle of the pumpkin. However, after driving it a few times, i realized this wasn’t a fix at all.

So, last week I decided it was time to do it right, to tear off the old spring pads and start from scratch and change the angling of the transfercase output shaft and the input shaft of the pumpkin to make them the same. Here were the steps.

1) Remove rear end and remove old spring pads and shock mounts and then drink beer.

2) Build new spring pads. More beer.

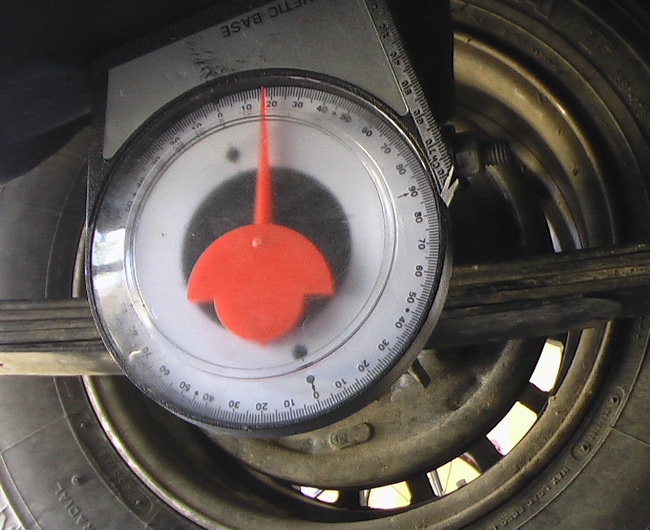

3) Connect everything back together to test the driveline angle. Uh oh, I discovered the driveline angle was 30 degrees (ouch), which allowed for almost no flex — not a good thing. Breathe. And Breathe some more.

5) After hmmming and hawwing, I decided I needed to drop the transfercase/transmission just over an inch. So, I removed the undercarriage. Get energy drinks ….

6) Redo the tranny/tc undercarriage — I had to cutoff the angle piece and weld a new piece onto it. More Beer

7) Reattach the tranny/tc — this resulted in an improved angle, with the tc sloping down 7 degrees. Skip beer and drink water.

8)Then, I rotated the pumpkin upwards 7 degrees. More water.

9)Next, I pulled everything apart so I could weld the pads. Margarita to celebrate potential success.

10) Finally, I slipped the rear end underneath and connected everything back together. The result was the driveline now angled 24 degrees. While not ideal, I can live with this for the time being. More beer …

Today, I finally got Biscuit back on the road. I have to say, I wasn’t entirely sure that all this work would to solve the problem, but I am HAPPY to report that not only are all vibrations gone, but also the noise I was getting during deceleration has disappeared as well. So, next week I’ll be heading back into the hills. The heat is finally here in Boise and all the snow should be gone from the trails.

Now, while I blame mom for a torturous month, it motivated me to fix everything correctly. Thanks Mom! And apologies to Robert Pirsig for the blatant theft of his book title .. Zen and the Art of Motorcycle Maintenance.

Here are a few pics (honestly, I was so mad about having to tear all this stuff apart that I didn’t document this too carefully).

Here is a pic of the rear end pulled. I’m about ready to remove the spring pads:

These are the new spring pads made from 3″ x 2.5″ tubing.

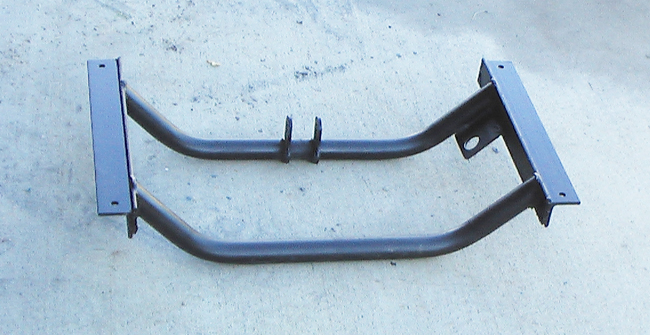

Here’s the undercarriage before I cut off the angles. You can see the replacement angle sitting on top of the carriage.

Here I’ve cut off one side.

Here it is complete. The result is the undercarriage drops everything just over an inch.

And, here it is finally back together :-). And the body leveled out just where I want it. Who would have thought a simple lift would cause soooo much trouble!

Springs, Things, Dumb Luck & My Birthday

Well …

June 5th was my birthday. For my 45th birthday, my mother gave me some cash and said ‘get yourself something special’. It seemed simple enough.

I decided to get myself the rear lift for Biscuit that I’d delayed ever since I discovered my rear springs weren’t quite as high as I had thought they were (can you say mismeasurement?).

Fortunately, I’d had the fore-sight (yes, it does happen now and then) to use some late 1980s cherokee springs in the rear, because they were inexpensive and widely used.

So, on Saturday June 5th I dropped by the Japolpy Jungle in Nampa, tools in hand, sun in the sky and enthusiasm high, for some shopping!

You see, I’d done some research and it turns out that the folks with Cherokees have been using Chevy S-10 and similar vehicles as low budget lift solutions. Simply using the eye-cutoffed main leaf, builders can achieve a 1″ plus lift.

So, I went in search for a S-10 of some kind. Low and behold, I quickly found a S-10 truck with no truck bed, which meant NO crawling underneath the vehicle — halelluah, it truly is my birthday 🙂

Even better, there was little rust, so the nuts and bolts came apart easily. Not only that, but I gained some extra karma by loaning some tools to a couple guys who hadn’t quite brought what they needed. I was set … or thought I was ….

After gathering the springs and a few extra hoses, clamps and other items, I left Jalopy Jungle and looked forward to a quick and easy lift.

Of course, it’s never that easy ….

As dumb luck would have it, when I first aligned my rear drive line, I set it up so that my drive line went straight out from my rear pumpkin and only angled from the transfercase.

A simple lift of 2″ with a couple of the leafs from the S-10 Blazer obliterated the dumb luck. 2″ of lift altered the geometry of the rear driveline enough to create vibrations that rattled the vehicle at speeds as low as 30 mph (seriously rattled). At first, I thought the vibrations were the result of bad u-joints, a bent driveline, a loose transfercase output shaft, and more. I also tried changing up the spring height, installing different variations of springs 7 times. Finally, because of the Dana 18 gears I installed in the Dana 20, I was able to rule out everything, but the rear drive shaft, because I was able to cruise down the road at 30 mph using the front drive line. So, the problem was with the rear driveline … damn!

So, I chose today (Saturday the 12th), a cloudless, beautiful windy day in the 80s when I should be jeeping, to be crawling around the garage finding a solution to the problem.

First, I started from scratch. I rebuilt the old springs and took Biscuit for a drive; good news, there were no vibrations. So, it was the lift and the geometry of the rear driveline that was causing the problem.

Next, I lifted the rear using only 2 long leafs from the S-10 with eyes removed. I also used a custom ‘angle leaf’ to compensate for the 1.5″ leaf. Finally, I positioned an angular measuring device on the bottom of the pumpkin to insure it didn’t move much.

Well, after 5 hours of work, I can finally announce success!!!!! No vibrations and I have my 1.5″ lift which leveled out Biscuit’s body. So, tomorrow I get my delayed birthday drive.

Not only that, but after testing 3 different fuel gauges, I have a fuel gauge that properly measures the level … So happy birthday to me!

Here are some pics of the painful, week-long process.

BEFORE:

Jalopy Jungle:

The Wedge:

Sizing up the wedge:

After the wedge: It’s amazing the difference an inch & a half can make!

Biscuit’s New Drain Holes

One little mod I’ve been meaning to implement was the installation of some drain holes for the driver and passenger side floors. This allows the interior of the body to easily be sprayed out after a day in the dirt.

I knew I didn’t simply want holes; instead I wanted holes with stoppers. But, I was concerned the stoppers would wear on the fiberglass. So, the other day I drove down the road and browsed around the local Home Depot store to see what I could find.

One idea I had was to check out the PVC aisle to see if there were any stoppers for PVC Pipe. After looking around, I discovered some $.15 stoppers that could fit into 2″ PVC I already had. So, I bought the stoppers and went to work.

First, I drilled 2″ holes with a drill saw. Then, I cut two pieces (one for each side) PVC to about 4″ (my fiberglass body has two layers of fiberglass with a foam core). I then used some handy marine glue to stick the PVC in place. It takes the marine glue about 7 days to cure, but once cure, it’s there for life. Here are the finished results — nothing fancy, but it gets the job done.

Here’s the hole with the stopper in place. I still need to put some herculiner around the edges to blend everything in better.

This image shows the stopper out and the top of the hole:

This image shows the bottom of the hole:

A May Day in the Hills (almost a mayday!)

Just the two following updates tonight. I’m gonna fix some food and relax tonight!

Today, May 15th, the Boise Foothills gods opened the gate at 8th South, which allows for four wheel drive vehicles to head up into the Boise Hills from 8th Street.

So, with the 82 degree weather, it seemed liked a perfect day to drive the mountain. Besides, my new tire carrier needed testing.

Taking off about 2pm, it took about a half hour from the base of 8th street to get near the summit, where a bypass road allows travel along the mountain ridge both east and west. Along the way, at one point I heard the passenger front tire collide with portion of the fender that sticks out too far. It make a very loud crunch and I saw the entire right side of the front clip lift a few inches. Clearly a design flaw! I got out to check out things out and my initial assessment was that nothing got damaged.

So, I hopped back into the jeep, drove upwards and, instead of reaching that bypass road, I chose to take a mini 4×4 trail off to the side to checkout the vista that is right before the bypass. That’s when things went a bit awry.

At this point, I got out and checked the fender more closely. You can see in the pic that a crack has appeared across the fender … oops! Moreover, there was some damage underneath the fender. No worries though, I can repair it all; it just accelerates the need to fix the ‘header bumpout’ on both fenders.

So, after checking out the fenders, I snapped some pics, got back in the Jeep, and, to my amazement, had a problem getting it started. The engine that was running perfect up to that point chose that moment to suffer some altitude sickness (it’s about 6000 ft there). It just stopped starting and running normally. And, without a clutch to feather, I had to rev the engine, drop it into reverse, and try to spin the jeep around so that I could point it down the tricky hill.

To make a long story short, I restarted the engine many times and feared the battery would die before I could get the engine working long enough to spin it around. However, I did manage to get the jeep pointed downhill and, thankfully, did not kill the battery; but it was far too close. So, I need to develop a strategy for managing the carb at those higher levels as there are many places at that altitude left to explore.

Here are some pics from where I stopped. You can see how the trail disappears in back of it. I had to spin the jeep 180 degrees and get it pointed down the steep incline.

Here’s the crack …

Here’s a shot of the carrier with the jack tied on to the back. I’ve got a solution for bolting the jack onto the carrier, but I’ll highlight that in an upcoming post.

Here’s me with some seriously ruffled hair enjoying the view. I have yet to discover the jeep won’t start easily.

Here’s a panorama.

Time to build a Tire Carrier

Among those odd-n-end projects I’ve been meaning to complete is the tire carrier. Since I don’t foresee installing a rear seat in the near future, I decided to build a carrier that would blend in with the roll cage in a way that the tire would be inside the rear area when I install a top (another odd-n-end to-be-done project).

My first decision was to utilize the same strategy for the carrier I used for the rear view mirror: cut a piece of roll bar tubing in half and use that as a mount to tie into the roll cage. I also wanted the carrier removable in case I wanted to add a rear seat and put the spare tire on the rear bumper.

In this pic I cut a section of tubing in half and then cut one of the halves into two pieces:

After widening them slightly, I have tested all three pieces on the roll bar:

On the longer of the three pieces, I have fashioned two sections of tube that will attach to the piece:

This tire mount was in terrible shape, so I decided to cut off the top piece and work from it:

Here, I have cut the mounting plate and have prepared some rectangular tubing for attachment to the plate.

You can see here that I have welded the tubes onto the half tubing. I also ground the square tubing pieces and welded those onto the round tubes. In addition, I welded the carrier plate onto the tubing pieces. Finally, I have added the lower bar and cut the tubes so they will conect to the bar:

Here are some pics of the finished product. Again, the carrier plate isn’t perfect, but I saw no need to waste it and it works perfectly fine.

A Beautiful Day for a Sunday Drive

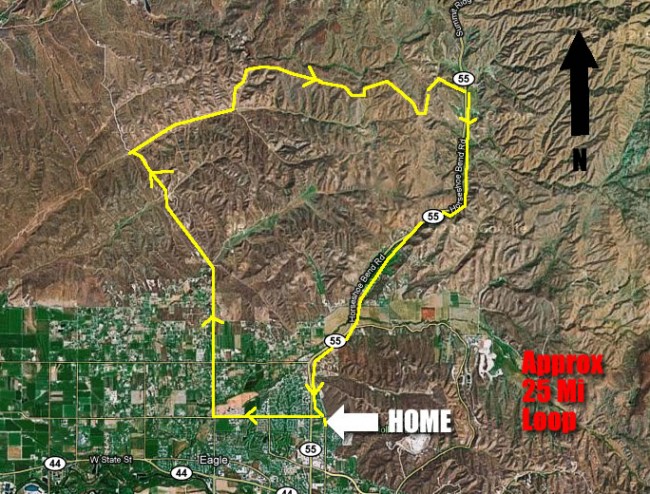

After fixing the sprinklers and getting the lawn ready for summer, I decided it was too nice of a day to waste any more it, so I pulled out my trusty Idaho map and searched for a local drive I hadn’t tried yet.

After fixing the sprinklers and getting the lawn ready for summer, I decided it was too nice of a day to waste any more it, so I pulled out my trusty Idaho map and searched for a local drive I hadn’t tried yet.

Sure enough, there was a dirt road about 15 minutes north of me that meandered upwards 12 miles into the mountains until it reached Spring Valley Summit (4500′) on Highway 55 between the Treasure Valley and Horseshoe Bend.

It was perfect, as I live just off Hwy 55, so I could roar down the highway following my exploration into the ‘unknown’ and test out my new timing specs (I just readjusted the distributor to 13 degrees). With new jets and the timing dialed correctly, it seems to be running very well.

Along the way, I snapped a couple pics for your viewing pleasure. In this first pic, I’m near the beginning of the drive. That’s Squaw Butte in the background, which I’ve only climbed halfway so far (prior to having the jeep).

There were a number of mines along the drive. Why someone parked a car onto of the entrance is beyond me … Maybe it’s called the Rusty Auto Mine?

Lettering and a Logo

Yesterday, I spent some time deciding how Lost Biscuit’s name should appear and where I might put an ewillys logo.

Building the Logo

The simpler of the two items to create was the eWillys logo ‘sticker’. I took an EPS version of the eWillys logo, increased the size in photoshop and then applied it to the jeep. You can see in the first image below, which is entirely a photoshop mockup, that it works pretty well.

However, when I increased the logo further, printed it out, and placed a paper version on the jeep, the logo appears washed out. I think I need to embolden the eWillys name to give it a darker appearance when printed. The actual sticker will be stuck to a thin plate (probably an aluminum plate made from a street sign which i can pick up cheaply at my local metal recycler). That makes attaching the logo, and getting it positioned correctly, easier.

Finally, after staring at it over the last few minutes, I have decided to put some more white space above the logo itself — it feels too crowded at the top. So, I’m going to center the logo a little more within the ellipse.

Creating Lost Biscuit’s name

Creating the Lost Biscuit name was more of a challenge, mostly because I needed to settle on a font. I knew I did not want a pure san-serif font (think arial, helvetica fonts), because I felt that would be too angular and void of personality. I didn’t want too much of a serif font (think Times or Garamond), as that would be too formal.

No, I needed something slightly modern and slightly whimsical, which is how I settled on an italicized Tekton Pro. After experimenting, I also decided to go with all capital letters (and increasing the size of the letters L and B) as it I thought it worked better visually.

In image 1, the photoshopped image, the size looks just about right. I tried it in black, but decided white worked the best. In the second image, I printed and cut out the letters, leaving small strips of paper to keep the letters connected. Unfortunately, after all the work of cutting out the letters, I decided that 4″ tall letters were too tall. So, I dropped the letters to 3 1/2″, which I think will work well (to be tested very soon). Once I finalize the design, I’ll head to a local graphics shop and have them made.

Sunday Trip over Rocky Canyon Rd & Aldape Pass

Sunday was a perfect day temperature-wise to take Biscuit out for a long test run into the Boise Foothills.

Of course, It took all of about 5 minutes into the hills before the engine overheated. For some reason the auto temp sensor wasn’t turning on the electric fans. So, using some extra wire i had, I wired up the fan directly to the electrical system, which bypasses the temperature sensor.

After resolving that issue, it took all of another 5 minutes before we hit a gate that wouldn’t open until May 15 … sigh.

So, I drove back down the hill, through town, and tried a different access road that’s on the East Side of Downtown Boise. This time, we found some trails!! We even found some difficult enough terrain to engage four wheel drive and low range.

After an hour of driving, we found ourselves at the top of a pass and made a left, tackling some more difficult terrain. We eventually hit some snow and figured that without a winch, turning back was the smart option. When we got to the pass, I made a left and headed down the other side of the mountain.

As I managed to leave the map at home, we were travelling slightly blind, so we depended heavily on serendipity. Eventually, we found ourselves at one of two tributaries to Lucky Peak Reservoir. Because the lake is low, we could actually drive along the reservoir, which is where these pics were taken.

Instead of heading back over the canyon road, I took the highway back to Boise, which meant Biscuit got to drive at 55 for an extended length of time. All in all it was a successful trip! Here are some pics from the day’s adventure.

Engine Update and the Invention of the PCV Valve

I made some more progress with the engine today. I managed to get the oil to finally stop exiting the dipstick hole. The cause was, as I suspected, related to the crankcase pressure. So, I spent some time fiddling with the PVC and breather system.

First, I bought a new PCV valve. Next, I connected the valve cover ‘breathers’ together with the intake breather and fed them into the aircleaner. Now that the pressure is a bit more equalized, the oil stopped getting pushed out the dip stick hole.

So one problem down, but now a new one. The air getting cycled into the air cleaner was ‘dirty’ enough that it was affecting performance a bit. However, I’m hoping once I get the new jets for the carb, it will stop burning so rich, which will clean up the system. That’s the theory anyway.

While I was researching breathing systems, I learned a bit of history about the PCV Valve. It turns out that PCV valves were invented during WWII to enable tanks to ford deep water and still have their systems breath appropriately. Following the war, someone at the GM plant where the PCV Valves were built realized they could help combat some smog issues. You can learn more about this at Wikipedia.

My Build: Adding a Rear View Mirror

I’ve been meaning to add a rear view mirror to the Biscuit. A couple months ago I pulled a rear view mirror off an old Dodge truck at a salvage yard; I specifically searched for a rear view mirror that could be bolted onto the jeep. I knew there were times that I would want to have a rear view mirror without the windshield, so connecting it to the windshield wasn’t an option. Also, from past experience, I knew that the windshield flexes at highway speeds a bit, so it would shake a little less connected to the roll bar.

So, last weekend I took a small piece of flat steel and welded it onto a piece of tube cut in half. I then drilled and tapped a hole into the rollbar. Then all that was left was to drill a couple holes into the mini mount i built, paint it, and attach it. It’s nothing fancy, but gets the job done!

Busy Week with the Kids …

It was a busy week with my kids. This was a pleasant surprise for me as it wasn’t ‘my year’ to have them over spring break. The boys continued to humble me with their video game prowess (with Call of Duty: Modern Warfare 2 the game of choice); however, I evened the battles by destroying them at scrabble and monopoly (yes, real boardgames!) — I still got it!

As usual, there was plenty of food, along with a special celebration of my daughters birthday that included some home made chocolate fondue (into which we dipped a variety of items). The chocolate fondue was inspired by a cheese fondue we enjoyed on Wednesday generously provided by the ewillys Swiss Bureau; So, many thanks to John and his family for that generous gift :-).

The night before the kids arrived (which was saturday night of last weekend), I attached the new heads. They appear to have solved the leaking problem. I still have some minor leakage of oil out the dipstick holder, but I think a little sealant should fix that. One very noticable change is that the engine starts very easily now (though the new battery and alternator are helping with that too). Now, I need to fine tune the carb (an older 500 CFM Performance carb) so that it runs a little less rich under heavy acceleration.

Below are a few pics of the kids playing for the camera:

I Finally Pulled the Head Today ….

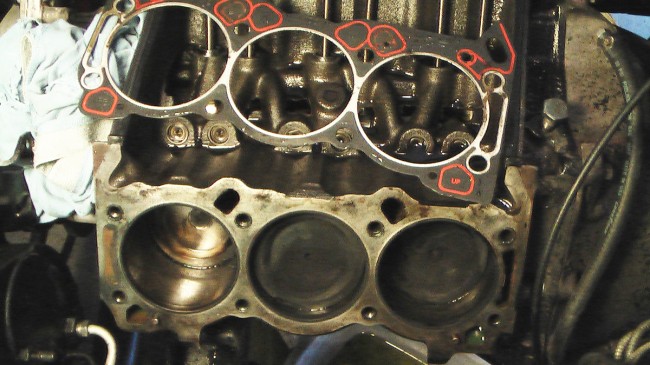

So, I pulled the driver’s side head and inspected the head and cylinders. You can see in the pics of the valves that the number #1 cylinder isn’t buring as well as #3 and #5. Also, number 1 cylinder looked a great deal moister inside as well. The head gasket appears fine.

I’m still uncertain what’s causing the problems as I haven’t spotted any cracks yet. As a refresher, here are the problems:

1. Some exhaust or blow-by escapes into the block and escapes out the intake manifold (or out the driver’s side head).

2. It sounds like it runs well until under pressure such as more than average acceleration, then it seems to run rough, until the acceleration is let up a little.

3. Some coolant residual appears in various places after running the engine (in the form of a slightly white foam).

4. I have leakage of slightly watered oil that leaks from the oil dipstick and from the valve cover. I can slow this greatly by disconnecting the PCV unit from the intake manifold.

Here’s a few pics (note cylinders #3 & #5 have a little liquid from pulling the head, but the #1 cylinder is much damper/oilier).

Crack in my engine block?

This weekend I spent some time messing with my engine. One of the concerns I have had was that the whitish smoke that still slips out of the intake manifold hasn’t gone away. I had hoped that was simply the rings not sealing, but I don’t believe it is anymore.

While checking the engine closely on Saturday, I discovered that there was some whitish, oily residue on the roof of the oil breather, which suggests coolant in the oil. My radiator level was also a little low. Between that, the smoke, and the fact that it runs a little rough when under pressure, I now believe that somewhere on my left bank there is a crack. I suspect it’s the REAL reason the seller of my engine stopped using it.

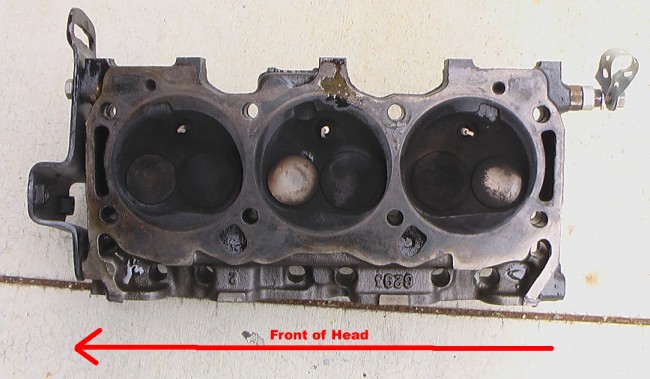

Fortunately, I have an extra 3.8L block that appears in good shape (I’m already using the heads and crankshaft). I would have used that block initially, except that it’s bored .030, while my Hypereutectic pistons are made for a stock bore. So, I guess I’ll go back to .030 bore and the pistons that came with that block.

So, I’m going to get my block dipped and cleaned, pull the engine, rip it apart, and put everything back together. It sounds like some good weekend fun …. I’m might redo the radiator setup while I’m at it — I have a new idea for that.

My Build: Climbing the Local Foothills

I finally got a chance to get Lost Biscuit onto the dirt today (Saturday). One of the unique aspects of Boise is that the surrounding foothills have been reserved for recreation. There are areas for hiking, walking dogs, biking, motor biking and four wheeling. One of the quickest ways to reach the foothills is to head north on 8th avenue from downtown. It takes all of 5 minutes or so to reach hiking and biking areas. It’s about 15 minutes to hit the motorized offroad areas.

My son Karson was with me. It was his first off roading experience. We were only out about an hour or so, as I’m being careful to push the bounds of the jeep slowly to let everything ‘settle’ into place.

On the positive side, the suspension is as I could have hoped. It’s firm enough for the corners, yet handles the bumps well. It’s a step up from my first suspension, which was a step up from the early jeeps I drove. We wound up the hill, took some side roads, tested out low range and four wheel drive.

On the negative side, I’ve still got a little oil that appears to be the result of valve covers that aren’t quite sealed correctly, so I’ll have to take them off to see what’s happening. Here’s some pics before we got muddy.

This is a pic facing west. Those foothills are all part of the foothill recreation system.

Here’s Karson with the hills and hundreds of miles of hiking, biking, four wheel drive trails, and the Bogus Basin Ski area behind him.

In this southern facing image you can see the City of Boise to the left and the entire Treasure Valley filling the background. I can’t say for sure what the pole is, other than a modern day totem of some kind?

My Build: Seat Covers

One thing I did not get with my $20 seats were seat covers (here’s another link on how they mount). Kim offered to sew these together for me and, since she’s right here, I could keep my eye on them as they were being made. These were sewed from the heaviest, nicest seat vinyl I could find from Beverly Fabrics. Best of all, it was 50% off.

The Prototype, which is on the passenger seat, could use a little adjustment still, but the second one turned out great. Both just need some rider time to get stretched and pressed against the seat so they will form more closely to the seats.