This article from the March 28, 1945, issue of the Farmers’ Weekly Review highlights the mobile welding capabilities of the wartime jeep. The article also notes that the Army tested the jeep on a 500-mile obstacle course before approving it.

Welding Shop on Wheels Is Big Help

Emergency Repairs Made on Field of Battle .

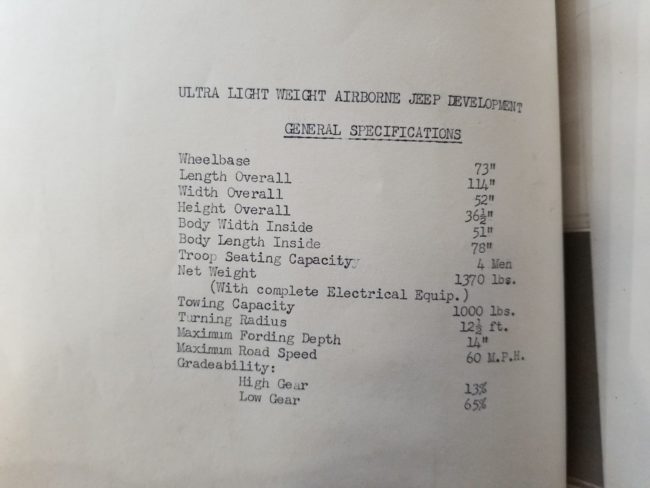

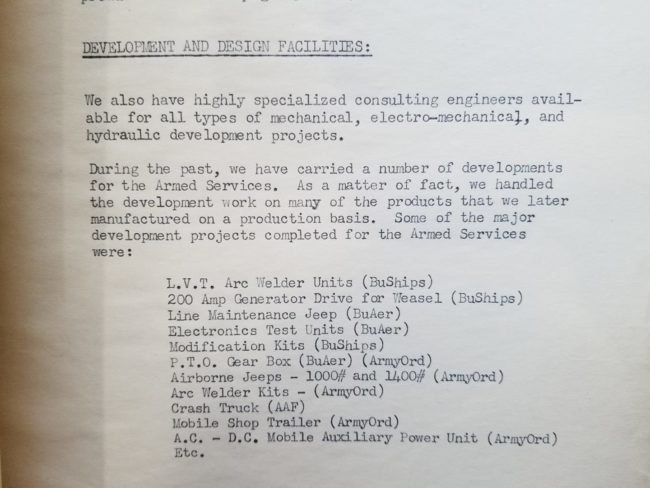

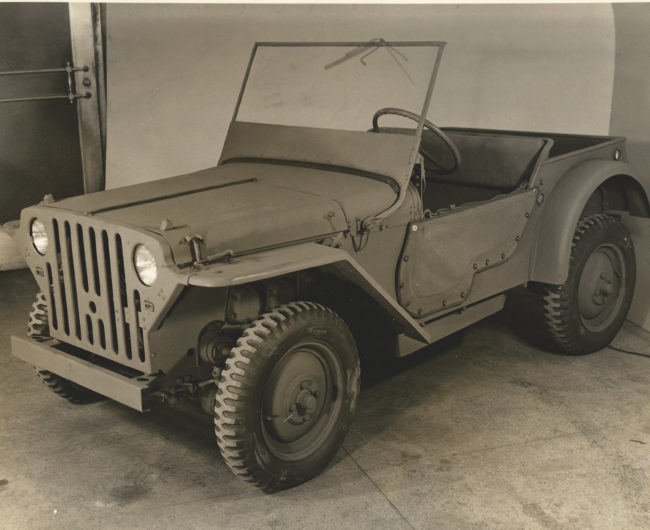

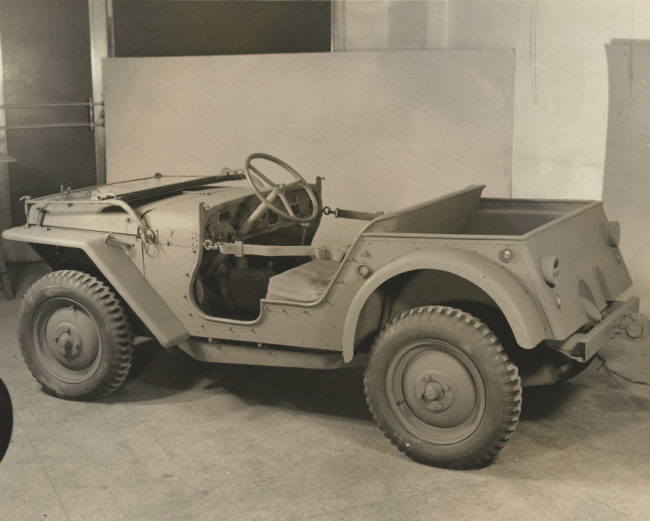

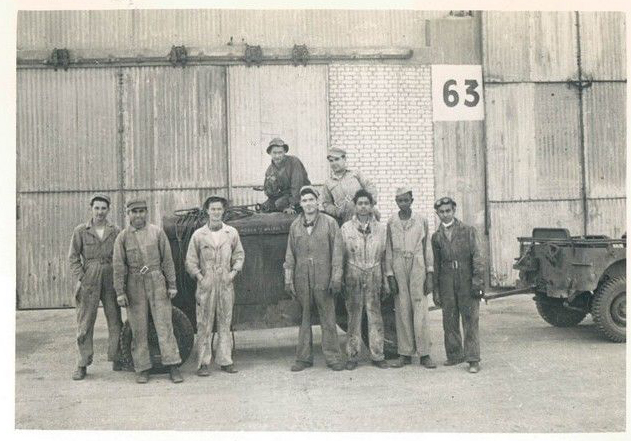

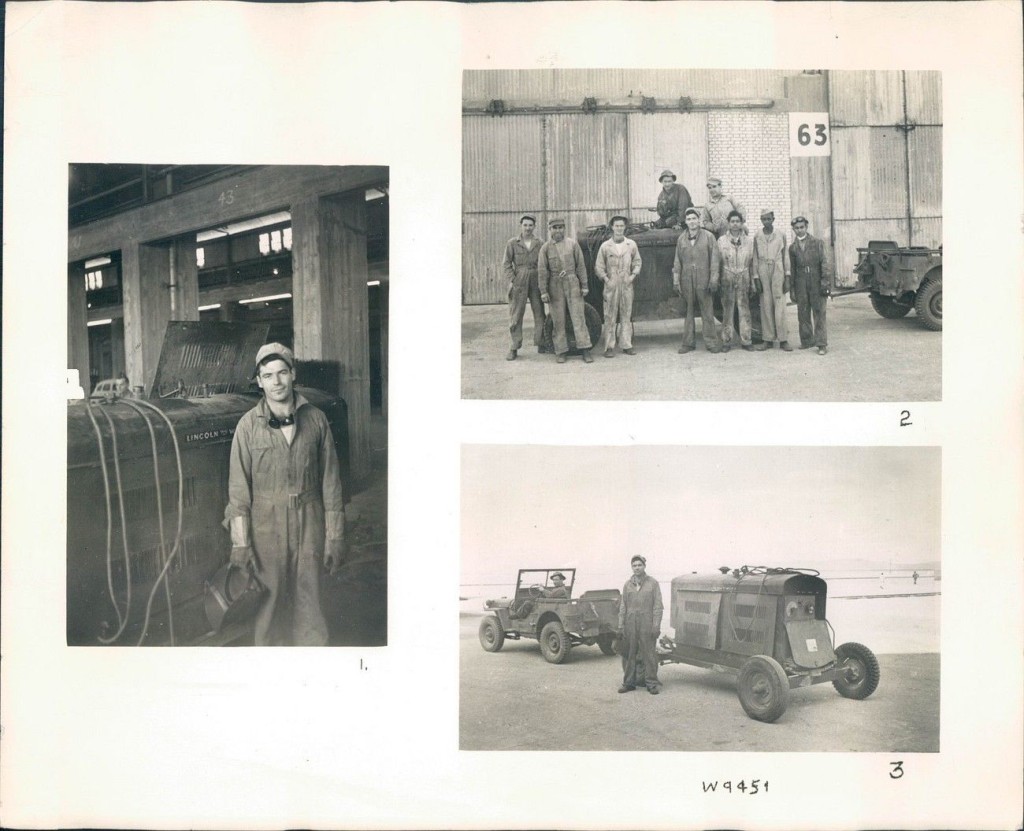

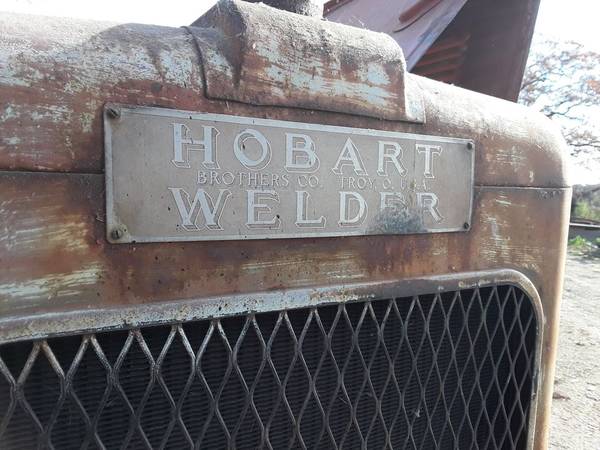

NEW YORK . — A highly mobile welding shop on wheels that can traverse ground which proved impassable to most previous maintenance vehicles has been developed by General Electric, in cooperation with army engineers, to enable emergency repairs of damaged war equipment to be made right on the field of battle, the company disclosed . Consisting of a standard army jeep bearing a specially perfected G-E arc welder, this mobile repair shop, according tc army reports , has proved invaluable in helping to keep front line equipment in fighting condition. In weight the G-E welder jeep is equivalent to a one-quarter ton truck, whereas the equipment it replaced consisted of a five-ton truck towing a one and one-half ton welding trailer. This weight reduction, plus the jeep s great maneuverability, enables the vehicle to readily negotiate rugged or muddy ground where larger and heavier trucks broke down. When desired for use in air borne operations it can also be loaded aboard a transport plane

Power to operate the welding unit is obtained by means of a V-belt which is connected to the engine of the jeep. As soon as the vehicle is brought to a stop the unit can be put in use. Proper engine speed is maintained by a governor, quickly disengaged to permit normal operation of the jeep. The welding unit is installed in place of the right front seat of the jeep, allowing the vehicle to carry a crew of three -men comfortably. Before accepting the welder jeep for service the army subjected it to rigid tests on a 500-mile obstacle course, the same course on which combat tanks are tested, and it came through with flying colors .”