I bought these two items off of eBay. If I understand correctly, these are mats, produced by the Congress Electrotype Company, were formed from an original engraving. They were then placed wrapped onto a cylinder with other mats to form a newspaper (or magazine?) page. A metal mold is then created from that, which is used to print the pages.

I had erroneously assumed when purchasing them that they would be thick, heavy metal plates (before I understood how the process worked), but they are actually extremely light and pliable. I assume these were extras, never used? They may be a paper mâché of some type (they are that light), which was one of the processes historically used, or something similar,

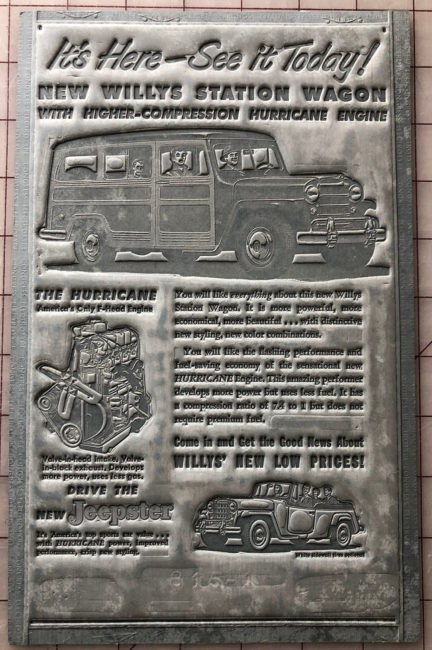

I’ve taken pics from above and at an angle to show the depth. I have to say that I’m not really sure these were worth buying, but I doubt many survived (these are the first I’ve ever seen anywhere).

This wagon ad is 10″ tall by 6″ wide:

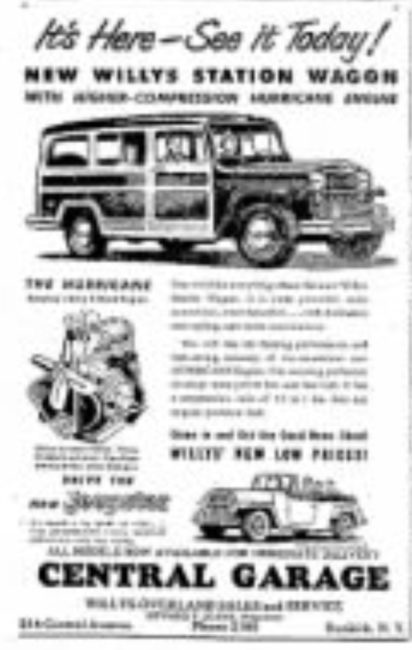

I was able to locate an example of this ad, but it’s a poor example (If you have a newspapers.com subscription, you’ll be able to see it more clearly):

Dave, are they Lead? Many or most printing plates from that era were lead. That would explain how pliable they are also. and the color certainly appears so.

Very cool, and a genuine piece of Willys Jeep history

Wow, those are very cool.

Cool nonetheless!!!

YOU OUTBID ME — when I worked in the newspaper business ( paperboy ) — I used to see all the lead printing stuff — I think they printed something and then threw it in a tank and melted it — so its rare to find old dies like this — this is assuming your articles are lead …

These are more like a pressed paper mâché. They are incredibly light and flexible. They were forms attached to drums from which the round printer metal blocks (made from lead? … don’t know the vernacular) that were inked and rolled onto the newsprint. I’ve seen anything like these … I thought these would be heavy, made from lead or some other metal.

Great score Dave…….really neat

With some creative thinking, you could actuly make your own prints, similar to linoleum block printing.

So cool!

Dave, your description of the commercial advertising printing process is essentially correct. Here is some additional detail from what I recall about 50 years ago; my father worked for a major newspaper, and I got to see the inner workings. Strings of lettering were produced by machines called “line-o-type”, which were like the size of a china closet, a classic keyboard layout, an operator, plus a small molten metal pot with an ingot suspended in it. The machine spit out the lettering strings with a 3/4″-ish tall rib along the back. All by manual input. The strings and other artwork were arranged flat, and then clamped together to form a solid piece. The “mat” blank was placed over the flat and pressed, transferring the image to the mat. I don’t recall exactly what the mat was made of, but it had to take the heat of the molten metal without deformation. It was flexible to be curved to make the circular plates, which were mounted on the press rollers. The metal was remelted after. It still staggers my senses what they went through to print a large newspaper every day, often with changing editions from morning to evening. Somewhere I still have a small script sample from the line-o-type machine with my name.

Useless information:

That East Congress address is right next door to a building I used to work in. It’s an I-375 exit ramp now.

A few streets north is where Wilding Studios was located that filmed a lot of the very early CJ2A ads.

Bill

Thanks RD! That’s helpful.

Mike, that’s true, but I need a few more hours in the day … or maybe another entire day within a day? And, I need someone far more creative than me!