Seth just finished his winter project: a VW diesel conversion on his CJ-3A. Last November he bought a 1949 CJ-3A, but didn’t discover it had a bad block until he pulled the engine apart. So he decided to install a VW engine, while keeping everything else as close to original as he could; it still has the t-90, Spicer-18, Saturn overdrive, Dana 25/41 (lockrite F/R). As a result, the new engine produces 110hp/190ft and he is averaging 38 miles per gallon!

I asked Seth a few questions. Here are his answers:

1) What gave you the idea to us that engine?

I’ve always been a fan of diesel swapped jeeps. My CJ-5 has a Mercedes diesel in it. When I started rebuilding the CJ-3A I realized the l-head would need some work. So, I thought rather than spend money on that, why not put a TDI in it? The engine was already sitting under the work bench as a spare for my daily driver (TDI jetta wagon). I have a small lathe & mill in my basement. It took endless nights making chips and taking measurements. But it’s in and it works!

2) Did you run into any unexpected issues?

I ran into many issues. Some were expected, others were a total surprise. My biggest challenge is that this was not a previously documented swap. So, I was on my own. Honestly there were a few times I almost threw in the towel. The biggest issue was just physically fitting the engine in the jeep. My goal was to keep the jeep as untouched as possible. that meant leaving the drive train in the stock location. I wanted all original driveshafts, cross member and trans cover, etc.

Though I was successful, keeping everything stock made the process a lot more difficult. The TDI engine has a massive oil filter/cooler housing that lands right where the willys ROSS steering box is mounted. I designed and machined a relocation plate to move the cooler/filter. This engine also uses a rear-mounted vacuum pump to control the vanes on the VNT turbocharger. Because of this I had to modify my firewall. I didnt want to do this, but it was unavoidable. There were just lots of little things, like having to run a reverse mounted alternator to make room for the turbo. Aside from that, it was all the other little things that are involved with an engine swap.

3) How’d you make the adapter for connected the t-90 to the engine?

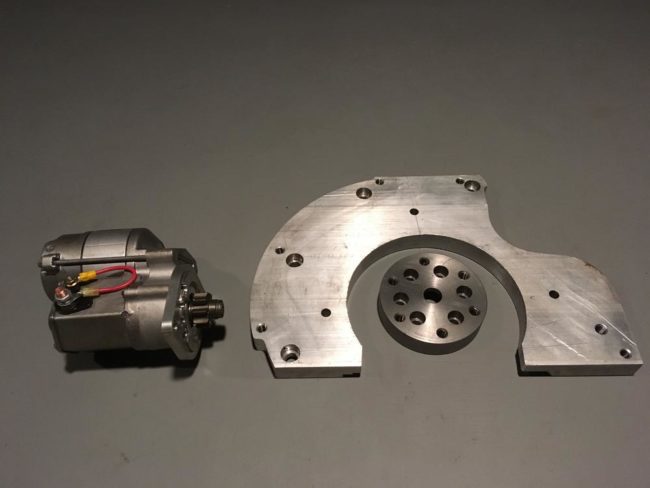

Making the adapter was time consuming but one of the more simple parts of the conversion. Like all my projects, it started with a pizza box and a sharpie. I made template with the box to get an idea of how i needed to make the adapter plate. My goal was to make the back of the VW engine be a carbon copy of the willys engine block and crank.

I used a 1″ thick aluminum plate bolted to the block. Then I centered the crank with the transmission using a dial indicator. Then, I made a crank adapter that bolts to the VW crank, but also fits the willys bolt pattern and protrudes the exact same amount as the willys crank. This allowed me to use the willys flywheel, clutch pressure plate and starter. In fact, I’m using a gear drive starter for a L-134. Also, I converted my donaldson oil bath filter to a paper element and fitted it with the Mass Airflow Sensor for the VW (for the factory Willys look lol). [editor’s note … nice touch :-)]

Wow. what a accomplishment, I am amazed at the high quality of your work, and most of all your patience.

Thanks mike! It was the most challenging project i have attempted. I learned a lot, messed up a lot, and had a lot of fun! Now that im driving it….totally worth it!

An amazing conversion done to better than factory quality. Well done!

Wow, like Mike commented, that is very impressive workmanship. a person would think that this jeep was designed this way. Beautiful Seth!

Build Thread

http://forums.tdiclub.com/showthread.php?goto=newpost&t=486421

K=U=B=E=L=W=A=G=E=N — O=V=E=R=L=A=N=D ???

What an engineering marvel? You are one smart man, and talented!

Love it. Much cooler than my factory diesel MitsuJeep. Great work!

Sweet build, I to drive a TDI, and have lots of Willys and it’s a mind blow to see an ALH in a Willys in line. I keep wanting to look at it from the driver side to orientate myself. : ) Now it’s time for bigger injectors, and a stage 3 tune!

That is just too cool!

I met Seth a few years back when I bought a XS400 based dual sport motorcycle be had built. The quality of this guy’s work is just remarkable, and he’s a really nice guy as well! Plus, he’s like 11 years old! lol…

Beautiful job Seth, as always. When it comes time to sell the Jeep…….

Hello,

I start the same conversion as you … I got a 1.9TD (aaz) that I want to fitter with my T90 on my 1947 willys CJ3a.

How to contact you privately to discuss your conversion?

Feel free to email me at captain_neto@yahoo.com if you have swap questions.

Wow Thanks Pete! It’s funny you should mention about my age…..today my daughter looked at me and said “you have grey in your beard like an old man” haha so your comment makes me feel better!

Hi Seth,

Yup, you are the man. I have a buddy who did the same. He has a great number of contacts and an exceptional talent being a traveling service tech for a large yellow company. He was stripping down the VW wiring harness when I saw him last.

My question is out of “No VW knowledge “ at all. Do I need VW wiring? Can I strip that 1.8 down to a true diesel tradition and run a mechanical shut off? (The reliable “pull rod” method)

Was you jeep a strip-down start from a chassis and build up with the VW in it or was it a straight up swap? Either way you did a beautiful job.

I have the Bridgeport and lathe on my side as well. More often then not, I ask myself why I did this! LoL

Great job !

Hi Seth,

My fingers are faster than my brain.

Just YouTubed an searched images online. I answered my question. It looks like old school method is out.

Good thing I’m getting the entire car.

That wiring will be essential.

Chris

AKA

Dumschittz

I am absolutely fascinated with your project.

I have a CJ3B whose engine needs to be rebuilt, but as a die hard Saab nut I have a 16v Saab B turbo parts car and engine lying about. I’m interested in doing a feasibility study of swapping that engine in as the Saab Bs are extremely reliable and I imagine the final product would have about 240 hp. Any suggestions would be extremely welcome, getting pointed in the right direction.

What tanny and transfer case did you use, looks interesting