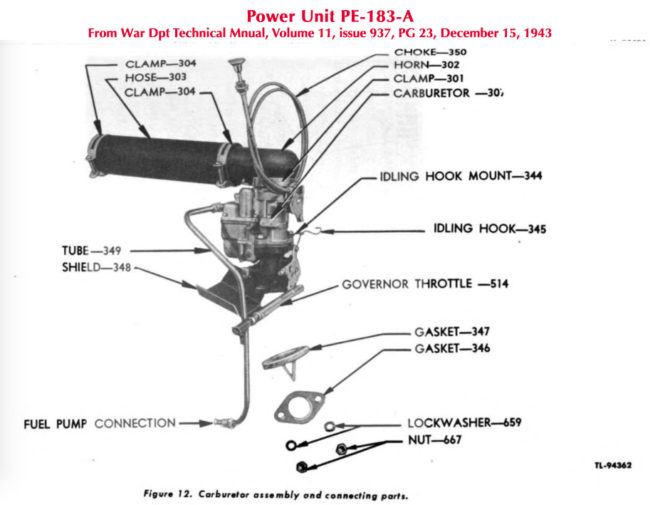

UPDATE II: There’s a reference to the shield in a 1943 Tech manual (pg 23). Still no part number.

UPDATE: Another heat shield on an industrial WWII L-134 spotted today (at bottom).

Barney Goodwin from Barney’s Jeep Parts shared a pic of this rare heat shield (he has several in his parts inventory). It mounts between the carb and the intake manifold. We’ve been trying to document a part number, pics, or other evidence of its use. The only evidence so far are two industrial engines with heat shields.

Here’s the heat shield Barney has in stock. Anyone have a part number for this?

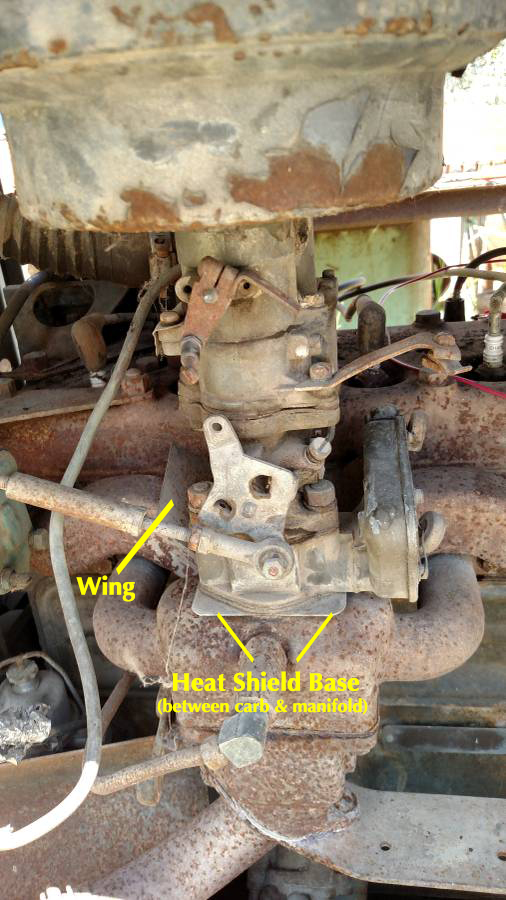

As sometimes happens, when I know what to look for, things sometimes pop up. In this case, after writing this post, I ran across a WWII Industrial engine for sale in Santa Cruz that has a heat shield installed. It’s hard to tell how far the wing sticks out.

When searching the industrial equipment archives, an image from 2015 of a civilian industrial engine with a heat shield with a heat shield popped up. The wing is more easily seen. Whether this heat shield is the same as Barney’s or not I couldn’t say for sure:

This Navy unit is powered by a L-134 with a heat shield:

Interesting that this would not be on all engines. Maybe its because of the expected continuous run times of an industrial engine on a pump or generator compared to the intermittent running of a jeep. Either way an interesting footnote to history that makes me smile. Thanks for sharing and for the research.

Mike, The immediate interest for this came from the 48 2A on the 13th that had a homemade shield. If things are as they should be on a regular Jeep – line routing, gasket, manifold damper condition, etc – this should not be necessary. But the power units had enclosed cabinets as did the Hobart generators using the Willys Industrial engine in addition to being stationary, needed all the help they could get. There are some good discussions on the forums about carburetor percolation in early CJ and none really address it with this item for the reasons just stated. We are trying to gauge an interest to see if we might make the part.

The first thing I noticed was all the engines with heat shields have the carb float bowl directly above exhaust manifold likely to save space or to create better use of linkages.

Very good observation peter45cj. I believe that’s the best answer to this. Thank you.

The M-38 came with a thick gasket between the carb and the intake manifold to prevent heat transfer during engine operation. This gasket also had a V shaped piece of metal intended to swirl the fuel/air mixture for better combustion.

Paul: I ran across that when hunting down the heat shield info. I believe this is what you mean: https://www.ebay.com/itm/Jeep-Willys-MB-CJ2A-CJ3A-M38-NEW-134L-Carburetor-Diffuser-insulator-gasket-/273778134226

– Dave

Dave, that’s the doodad I remember using when I replaced the carb on my old Willys. I tried the thick gasket with and without the swirl device and I couldn’t tell any difference in engine performance. I did notice an increase in performance when I replaced the original four cylinder engine with a Buick 225 V6.

What a surprise! That’s all …… Alaska Paul

Paul, another Willys mystery solved! That’s a good day 🙂

That ‘diffuser’ gasket was used on MB/GPW’s as well as CJ’s. Not unique to the M38.