This photo provides a good look at how frayed some of the wire was behind the speedometer. Worse, this wiring was sitting on the metal brace!! in the background is the volt-a-drop which provides stepped down voltage to the King Seeley speedometer).

Electrical Mess:

We’ve been working hard on Patterson the last couple of days. Most of our time has been consumed with checking wiring and rewiring stuff. Between frayed wires and mis-wired stuff, it’s filled our time. Apart from the types of frayed wire seen in the pic above, I discovered 1) the wires to the amp gauge and light were wired into the oil light (fortunately, all I had to do was pop out the light and plug it into the amp light), 2) the amp light was missing altogether (thankfully I could steal one off of Rusty’s speedometer), 3) the ignition jumper that screws to the back of the speedometer was laying on the metal brace (must have caused some shorting), 4) the oil light wire was wired to the fuel gauge (which explains in part why the fuel gauge didn’t work … well that and there was no wire connected to the fuel tank wire.

Dimmer Switch:

The dimmer switch has been lubed, reassembled, de-painted, and installed.

The Horn Wire

Patterson came with a button attached to the side of the steering column that was used as a horn, but it didn’t work. Since we were already changing some of the wiring around, we decided to steal the column shift button wiring from Rusty’s steering column I wired last month and use it on Patterson.

To start, I knew we had to run some non-electric wire (similar to bailing wiring) through the length of the column in order to pull the horn button’s electric wire down the shaft. That sounded like a good idea, but several attempts at pushing the wire up the column were a failure: the wire kept getting snagged as I pushed it up the column. I was getting frustrated.

But then, my genius wife had an idea. Why not blow some thread down the column using an air compressor nozzle. Once the thread came out the bottom, we could pull the bailing-like wire back through. I admit, at first I thought it sounded a little crazy. After all, near the bottom of the column shaft it narrows, so I thought for sure the thread would be stopped by it. But, then I took a breath and thought …. hmmm … what could it hurt to try?

Sure enough, she produced some thread, dropped a little down the column, then stuck the air nozzle into the hole. That thread blew threw the bottom of the column in a couple seconds. It was genius! Well, almost genius, as we had to upgrade our thread to thicker thread. Other than that, we had the column horn working in no time!

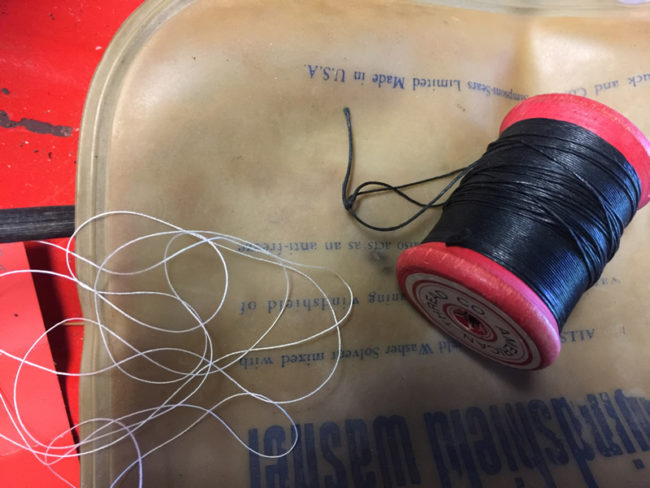

This is the thin thread we tried. It didn’t she enough tensile strength to pull up the wire. She just dropped some thread in and the air blew the rest of the thread down through that small hole at the bottom.

Once we shifted to the thicker, black thread it worked perfectly.

The black thread was able to pull up the wire. I had bent the end of the wire over about a half inch, creating a hook. Then I tied the thread in a loop and looped it over the hook as it stuck out the bottom of the column. Then we pulled the thread up through the column and the wire followed.

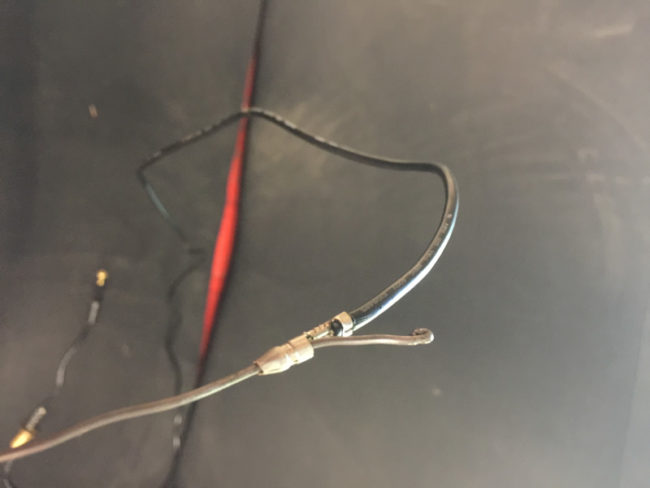

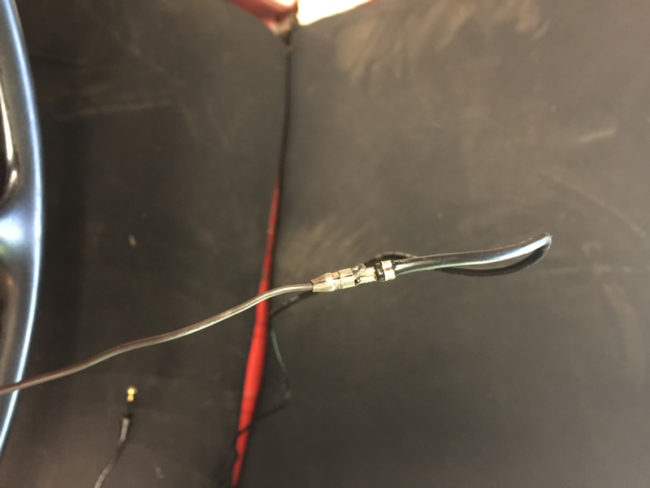

Here you can see I have slid the metal wire through the end of the horn wire and created a little bend.

Here the metal wire is snug within the horn wire’s metal plug. The bend in the metal wire keeps it from being pulled out. It also streamlines it making it easier to fit through the small area at the bottom of the column.

And here’s the installed button. We just have to add the rubber cover and we are good to go!

Tomorrow morning we plan to do (hopefully) the last bit of wiring when we fix lights just under the dash at each end of it. Since there’s a switch already in place, we figured we’d repair the wires and use it. The lights will light up the floors of the jeep. It still isn’t clear to me why the lights are there, but we’ll use them anyway.

I also have to build some kind of setup to hold a CB and a cigarette lighter (the latter for keeping a road camera and cell phone charged). I also hope to take Patterson for a short drive down the block and back. We’ll see how it goes!

No surprise there, Ann’s can-do problem solving military mind comes through with a solution.

Dave,

Never underestimate what a women can do. I remember all the things my Mother could do with a hairpin.

Go Ann go!

She is definitely a keeper!!!

Thanks guys. However this was written BEFORE I upgraded Patterson with glitter paint. HA, David’s opinion may have shifted back to questioning my sanity.

Sparkling Ann. 😉