I pulled the head on Patterson last night. I don’t see any cracks in the block nor do I see any obvious signs of coolant, though there might be a tiny bit of residue on the tops of pistons 1 and 2. My initial reaction is that coolant is entering the oil elsewhere. The engine does appear to have a recently replaced water pump. Anyway installing that incorrectly would result in mixing coolant and oil??

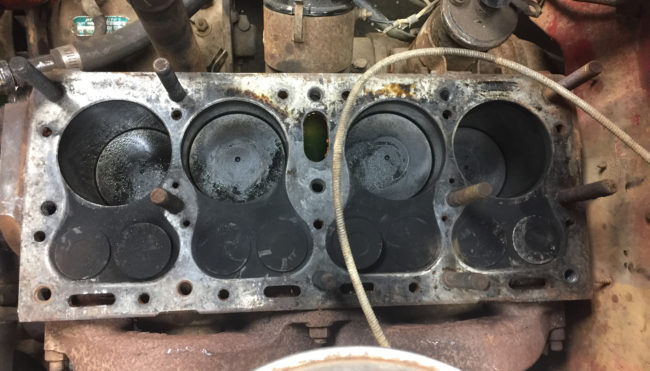

The first two photos show how the pistons and head gasket looked right after pulling it.

Then after pulling off the gasket and vacuuming up the dirt:

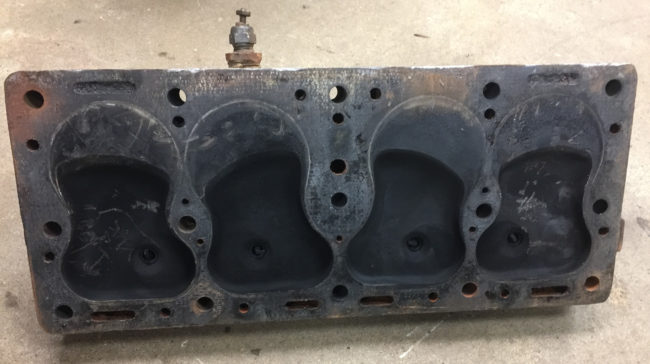

The bottom of the head:

Did you get to do a compression test before pulling Patterson’s head off? I would say to you first is follow the rust patterns I can see and the cleanliness of the one cylinder/piston. That gasket is worn slap dab out and I would bet that is/was the problem. What was the radiator level before running the engine. However I would still tear it down completely and have it checked out. Good luck!

Might as well finish pulling the engine at this point. Tear it all the way down and have the block and head magna-fluxed. For what it will cost at this point another $30-$40 bucks to be sure the block and head are solid should be a gimme. That way, you can inspect the clutch, motor mounts, master cylinder, etc much more easily..Personally, I’ve never been successful trying to take shortcuts in engine rebuilding.

possible water pump failed and coolant got in oil. they put new pump on and did not change oil. might call last owner. I would reassemble with new gasket and change engine oil a few times to see if it cleans up. watch coolant level and measure the amount of oil

that comes out [4 qts in,4 qts out. ] if there is still a leak then pull engine. worth a try for the price of a gasket and some cheap oil. [put the good stuff in when your done if it is working.]

There is usually a weak spot where a couple of the head studs are in water jackets, especially between 3 and 4. The water will come right up the studs and if you don’t have a very good seal on the head gasket and block, you will get water in the oil. When I did the aluminum head on our Surrey, that was a noticeable problem, along with the white smoke! We replaced all the head studs, had the head magnafluxed and resurfaced and put it back together and it has been fine. You still have to re-torque the head a few times to get a good seal. I used a Fel-Pro Blue gasket with spray on copper to get a good seal.

I agree Colin P. and a good point. I would have the head milled too if it passes the test. Don and Bill good points too!

I think the best strategy is to test Rusty’s engine. It’s marked as a rebuild, so it is entirely possible it doesn’t have that many miles on it. If the compression checks out, it could be worth dropping it onto Rusty’s frame and give it a test run. If it runs fine over the course of a few hours, I’ll drop it into patterson and put off rebuilding Patterson’s engine until later in the year.

OH, and thanks for all the suggestions. I do appreciate them. I do think rebuilding the whole thing is the right course. The engine has 60k miles on it at this point.

Good olé Rusty might just be a good donor temporarily. Keep on plugging away Dave!

If you decide to put Patterson’s engine aside for a while, I would flush out the old slop as best you can. Otherwise, the water laden oil sitting in places like the oil pump, the oil galleries, and crankshaft bearings could cause corrosion problems you’ll hate yourself for later. If you can drive the oil pump externally with a drill (pardon, I have no experience with these engines) while rotating the crank and replace oil a few times, probably would get it.

If you didn’t get a lot of white smoke from the tail pipe, or hydraulic lock, I’m not so suspect of the head gasket in a flat headed engine.

Murphy’s law, if it’s not broken, don’t fix it applies Hell of a time to figure out if Rusty’s engine is a runner, first thing I would of done after I dragged it home was try to start it. Ok, so be it, I’m always the “CRITIC” just need to point these things out.

Having said that, the flat heads were known for water in the oil problems going back to the beginning of time. Uneven torque on the head bolts could cause a problem like this over time. Too late now to check, but this is what was done first before before we pulled the head, back in the old days This is where the “old Guy’s” knowledge came in handy. (Thank you Mr. Verga)

First I think Dave can do whatever he thinks is right, he’s human and a grown man and man enough to admit his mistakes. There’s no need to be so harsh and critical of his intentions. If I’d done that with trainees they would have lost their confidence and unable to make decisions let alone the right ones. Now I’ve not told him I’m a Master Mechanic for my own reasons. But that head needed to come off period. The head gasket was worn completely out. Had it purred like a kitten and had no other fluids in water I still wouldn’t have wasted my time torquing down head bolts. Why? Because of the long journey ahead and unknowns of that engine. Simple. I know Murphy’s Law very well and its not if it ain’t broken leave it alone. It’s goes something like this, If anything can go wrong, it will! Plan B kicks in and so on. Plan for the worse and hope for the best. I think Dave can and will learn from this and that’s a good thing. No for some positive reinforcement, Dave keep chugging along I know you’ll reach your goal. Head scratching, knuckle busting, cussing, and all the stuff that goes on with the learning process.

Dave, I know you will get this problem solved. Like Barry says about Murphy’s Law, if anything can go wrong it will. Anybody ever been on an extended Jeep trip when something didn’t go wrong. You do the best you can and try to cope with whatever goes wrong. The Alaska trip presents a myriad of situations that hopefully the caravan crew will be able to handle!

Another thing, when I had the aluminum head re-worked, I gave the new gasket to the guys who did the work and they matched the head to the gasket to make sure the seal was going to be good. No overlaps, all the holes lined up with the gasket perfectly and the combustion chambers matched the outline on the gasket. Just extra insurance. Those guys did a lot of VW engine work and especially Flathead Ford stuff. First time they had done an aluminum head for a Willys. They did a great job!

I’d flil it back up with oil with some engine flush or a small amount of diesel fuel added and turn it over a few times, then drain it all out again to help get the moisture out. Then fill with oil again.

Clean everything up immaculate and even check surfaces with magnifying glass. Also close up pictures and then blown up works wonders I’v found.

Next I’d try a new head gasket and button it all back up. Torque it correctly of course. I even like to heat that head up real good with a heat gun and check torque again before even cranking. Takes a while but at least that gaskets been heated up good before the fact. That may be useless but it’s what I like to do. It takes a while keeping the heat spread evenly.

Next a cold compression test just to know. Even though my motor was running good when taken apart it had a broken oil ring. Glad I found out before it started scarring things up.

Cheap oil will work for the flushing and tests.

Then start it up, all the time, crossing my fingers that this solves the problem. Stranger things have happened!!!

Everybody M-E-L-L-O-W, I still talk like a NJ Guy, Watch some old KOJACK reruns, You’ll know what I mean.

Great ideas everyone. I do appreciate them. And, I also appreciate Kojak’s sober take on things … sorry Mike, I couldn’t resist after your Kojak comment :-).

Mike was correct in that the first thing I should have done with Rusty was test the engine; which is in fact what I did. However, I quickly discovered the fuel pump was bad. Chris McKay offered me a fuel pump from his bin of jeep parts. So, I put the engine aside temporarily and began disassembly, which led to a need for some more parts. At that point, I elected to focus on cleaning/painting the parts I had and identifying the parts I needed to make reassembly quicker. By keeping my parts costs low I figured that, if need be, I could locate another engine if the engine didn’t work out.

I am back in Pasco for a few days. On Sunday morning, we head back to Seattle for more time with Patterson and Rusty. Ann will be with me, so I can have her do a few things while I check the engines more carefully.