UPDATE: Thanks to Brett, I’ve added some photos of a later model General Supply V4 (possibly a Ford V4) at the bottom of the post.

Rick Webb shared what he knows about the history of General Supply Compressors & Hesse Compressors. His father Paul Webb played a principle role in the compressor’s development. I’ve included pics below to show how much alike they looked.

For reference, this is a General Supply GS-250 Compressor powered by an L-head. More pics here:

Contrast the one above with this one, a Hesse Horney Compressor powered by an L-head. More pics here:

Rick began, After reading information on youtube and the forums it seems as though there are a lot of questions concerning the hesse hornet and the gs-260 air compressors.I don’t claim to have all the answers however I can shed some light on the development of these units.

My father, Paul Web, lost his dad at the young age of 24 and took a job at the General Supply and Leasing Company in Kansas City, Missouri, in 1951 as a delivery driver. A division of the McDowell Tire Company, General Supply sold tire changing equipment.

When he took the job he met a man by the name of Dick Roberts who was an engineer. They soon hired a man with the last name of Simes (pronounced “Sims”) whose first name I do not recall.Simes was from Arkansas and was a self taught mechanic. He could not read or write, so they taught him to sign his name so he could cash his paycheck. He never used a torque wrench; however when his engines were tested his torque specs were spot on.

At the time, they were using Model A engine powered compressors for tire trucks made by the Gordon Smith Corp., when they learned Ford was going to quit making the Model A engines. So, the engineer, the mechanic, and the young student set out to design a new air compressor. They approached GM about using the all new small block V8, but GM wouldn’t warranty the engine after it was modified.

Next, they met with Willys Motors. They reached an agreement. Then they had to develop a custom head for the L-134 engine. These heads were cast from iron in Coffeeville, Kansas. The pilot valve and air valves were custom designed and my father received patents on these, which he sold back to the company for $1.00.They utilized a stock engine, swapping out the head for the newly designed one and slightly modifying the carb. The result was an engine that ran on two cylinders and pumped air on two.These proved to be highly popular and were found in many tire trucks around the country. They were basically stock engines and repair parts could be found in most major cities. They went on to produce approximately 12,000 jeep-engine powered compressors.

About this time, the Hesse Corporation copied the compressor and renamed it the Hesse Hornet. They, too, were built using jeep engines.

Soon thereafter Kaiser announced it would no longer make the L-134 4-cyl engine.The General Supply trio set out once more to create a new design based on a V6 and a Ford 4-cyl OHV. This design would not succeed as the lower ends were too weak and were soon discontinued.

A new design was developed utilizing the 302 Ford engine running on 4 cylinders and pumping on 4 cylinders and proved to be wildly popular in not only the tire industry but also in the construction industry as they were lightweight, simply designed and parts were readily available. Once again, the V8 heads were cast Coffeville, Kansas, and the V8 used the same air valves and pilot valve as the L-134 4 cylinder jeep-powered compressor.

In 1983, Mr. Mcdowell turned the company over to his son. The younger McDowell computerized the business. He also demanded that torque wrenches be utilized and records kept on the new fangled computer.The engineer was no longer allowed to draw his designs in chalk on the floor. Within a year, the multi million dollar company was bankrupt.

Mr Simes passed before the company went broke. and Mr Roberts found other employment. When Sims died it really hit my dad hard as they had become very close The company was sold to Iowa Mold Tool Company. They carried some compressor parts for a few years, but I’m not sure what is available today. Mr Roberts passed about a year ago. We lost my dad in 2010 the morning 0f his 80th birthday.

I hope this sheds some light on these machines as they were very popular at one time.

Thanks again to Rick for sharing this story. There are a few forums where members discuss the GS-260.

- https://www.smokstak.com/forum/showthread.php?t=117523

- http://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=toolt&th=7397

Here’s one of several videos of a General Supply GS-260.

———————————————

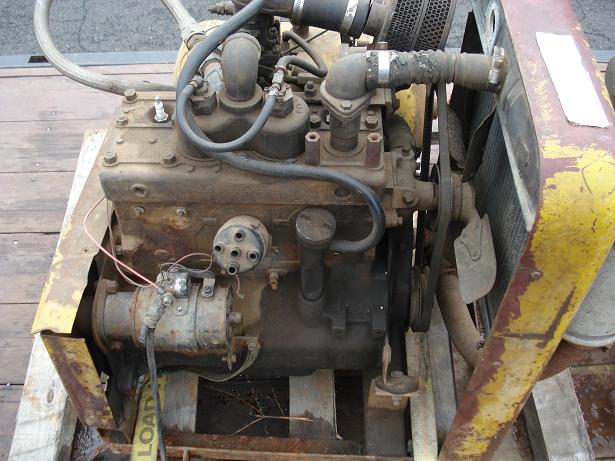

Thanks to Brett, we now have some pics of a Porta Air V4-35 compressor manufactured by General Supply.

I want one! I’d like to use one to supply air for my blast cabinet. How cool would that be?

I will sell you one!!!

I want one! Been kind of looking for a while. I’d like to use one to supply air to my blast cabinet. Wonder how big of a tank I could hook it to.

I have a cly head and all of the relate parts to make a Hess-Hornet compressor from any

Willys L-134 Engine, even propane if wanted.

Willys Mpls

louie larson 612 802 1860

Bloomington Minn 55420

I have a Hesse Hornet which I would like to sell, been in storage, engine was pickled, turns over, needs work. Located in northern Indiana. Email me if interested. hpkmeyers@comcast.net.

I also have one for sale $900. rsnboomer@hotmail.com. Complete on included small trailer. Kansas City, MO. Thx.

This one just appeared for $350: https://muskegon.craigslist.org/hvo/d/vintage-willys-air-compressor/6551939433.html

do you have a pdf copy of the manual you could send me

Hi Rex,

Unfortunately, I do not have a hard or pdf copy of a manual.

– Dave

I came across one made by General Supply called Porta Air V4-35. Was looking for any info on it. It is a v4 of some kind. Similar to Willy’s but newer. Any help or info would be great. Hope this isn’t the one with weak bottom end.

Hi Brett,

I’ve never heard of the V4-35, but I’m also not an expert on these. I did find an old reference (https://vsaab.yahoogroups.narkive.com/71nivUnq/v4-engine-on-ebay) that a Ford V04 was used in those. Maybe someone else knows more.

I can send some pics if you want.

sure … send them to d@alaskaorrust.com. I’ll post them in case someone in the future has more info.

Thanks!

– Dave

thats belongs to me its forsale $500 949 354 7836 thanks chris

Where do I find parts for this type compressor?

I know this is an old post, but about 6 years ago I got an old Porta Air V8-100 that used the Ford 302. I was able to find out that Iowa Mold Tooling (IMT) bought the rights and called them a model DA-8100. You can find the manual online. It uses that same General Supply parts. I was able to get some parts quotes back then but recently I found out it has all been discontinued. Maybe some warehouses still have parts. I just pulled the motor apart this week and it was obvious it was left outside a long time. I’m getting another 70s 302 to rebuild and put these parts on.

The patent for the unloader is US2968433A. You can find it online. It has a great cutaway view of the valve assembly.

Brett, I appreciate you taking the time to share that information. You never know who it can help!

Thanks,

– Dave

I am curious, are you sure it was a 302? I don’t remember who made them but we owned 2 in the past and I have seen a couple others since then, but they were all 351 Cleveland’s with the dry intake manifold’s, not wet like the Windsor’s, not saying their were not 2 companies making them, and chose two different block’s to avoid copyright. just don’t know why 1 company would make 2 such functionally identical parts that were not easily interchangeable. and yes I’ve heard of the Boss 302, and ford did a ton of work on those Windsor blocks to take a Cleveland head, not a cost I see a compressor company willing to absorb. otherwise great article.

You had me worried since I just picked up another 302 to swap the compressor parts on to. I went out to the shop and confirmed that the original engine is a 302 ford. I know Smith and Grimmer Schmitt both also had v8 monoblock compressors. Some other models used big block motors to get higher cfm. Mine was never a tow behind, the guy I got it from scrapped an old tire service truck and this compressor was in the utility body.

Grimmer Schmitt set off the bells, ours were both trailer, if we were mobile mechanics/fabricators, our service trucks in the gas V8 days had the big V4 compressor that clutched off the truck engine crank, but if we had a big fab or paint job where sandblasting of running a lot of air tools like 3/4″ or 1″ impacts we used the trailer units, once we moved to 5 ton IH service truck we went with screw compressors driven of the trucks hydraulics, as well as the welders and Hiab’s, as well right around that time our dad who was the welder past away, so those old girls and parts all went on to new homes and owners

I have a Ford 302 compressor.

The compressor head is marked with

G 801& G 802.

Looking for rebuild parts

Any ideas?

We have an old Smith compressor at my workplace.It has a Ford 302 with points in the distributor.I believe it was built around 1970.Not sure where you would get compressor specific parts for it.we have not needed any.These days it is only used in the fall to blow out waterlines.

Mike, it is probably the same as mine. Mine is in terrible condition and I’m working to rebuild it. My head is marked G 8**. The numbers rusted away. Hopefully you have the major compressor parts. Google “DA8100 manual” and you should find the pdf from IMT. The compressor is only since obsoleted and they have very few parts in stock, but the manual is helpful to see how it all goes together. I was able to get some of the graphitic gaskets that go between the threaded retainer and valve body and some of the big o-rings that that seal the top of each valve against the intake cover. Those parts were cheap. I went though Dejana and gave them the part numbers from the IMT manual. The vee packing that is used on the 4 unloaders and idle controller are no longer available. Mine are too old and hard to use and I’m going to look at McMaster Carr to see what seals they have a U-Cup seal that will fit.

My intake and discharge discs (hardened washers) are badly pitted. I measured them to be as follows:

-Discharge – 3.25″ x 2.5″ x 0.05″

-Intake – 2.44″ x 1.44″ x 0.06″

I found that the intake matches the Gardner Denver 90V3 disc perfectly (2.439″ X 1.435″ X .060″) but I haven’t ordered them yet. https://www.ecompressedair.com/ has them for $13 each but the shipping is oddly high. I’d call to see what is wrong.

The discharge disc closely matches the Cooper Bessemer VPM1-018 #9 disc (3.250″ X 2.500″ X .062″)

White Superior A906-759 disc (3.250″ X 2.500″ X .062″). Both are thicker and I’m not sure if they will decrease performance.

Good luck with your compressor. I have lot to do to mine. For example the aluminum hex caps on the top of the brass unloader tubes have almost corroded away. I’m making some new ones.

We do have a parts breakdown for it.it is a model 90 I believe.not sure if that would help anyone out or not.

Brett & Doug,

Thank you both for the information.

My compressor is in very good shape. No rust.

It still had antifreeze in it when I started taking it apart. The air filter cover has IMT on it.

Now I know what it stands for. It sat in the back of my shop for over 15 years. Now it is 1 of my retirement projects.

I have a portable air v4-35 compressor like the one posted. engine needs a rebuild one cyl low on compression. On running side of engine.it all their including the hood. I’d like to sell it. I have to many projects if anyone Interested I’d take $100 for it.it in TN and would have to be local pickup. Cantact me at joelcwalker50@gmail.com

I guess I never checked back in on this back in ’17 and missed all the offers. I’m still interested in one relatively local to PA.

Also, were all the industrial heads regardless of application (generator vs welder vs air compressor)?

Dave,

Were you asking if all the industrial heads were the same? I want to say there were two types, a standard head and modified one for some industrial applications, but I will have to research this do double check.

– Dave

Just for fun I started a Facebook Group “General Supply Air Compressors” if anyone is interested. Right now it is just me posting about my V8-100 rebuild. Slowly making progress.

Brett,

Good idea. Can you share the link to the page?

Thanks,

Dave

Sure, Try this link: https://www.facebook.com/groups/921938105037554

If that doesn’t work, just search for “General Supply Air Compressors” in the groups section.

I’d like to see more pictures of other peoples machines. I know I’ll need help tuning this thing when I get it going. Lots of adjustments on the air side. I put a few files in the files section like the patent and a couple manuals.

The link worked perfectly.

I had to delete the facebook group. I should have make it a “public” group not private. I don’t expect a ton of members, but I think it would be helpful for people to see the posts even if they are not members. I started a new one that is public since you cannot change that setting once private is selected. the new group is:

https://www.facebook.com/groups/988851565248039

Sorry for any inconvenience.

Very interesting history. I am very familiar with the Willys 134 engine in my flat fender Jeeps. A few years ago in the iron trader there was a Jeep compressor advertised and I bought it. I’ve had it running. I am now in the process of restoring it. I worked for Goodyear tire and rubber company as a contractor serviceman on dams and big road jobs. My first Goodyear truck had one of these compressors. It was fascinating, worked very well and put out lots of air. To push a 1 inch drive impact wrench and air up the giant earthmover tires

I have a hesse hornet it’s complete and runs great $1000 obo. in kansas

You can send in photos and contact info to post@ewillys.com need a few things like city close by.