UPDATE: Paul just forwarded me a new video of his nicely modified flattie. He first sent me pictures of his jeep back in 2008. Below is the original post.

httpv://www.youtube.com/watch?v=LgJPOX1QIoM

Published November 14th, 2008

Paul wrote to me the other day, professing he’s stricken with the dreaded flatfender disease. I told him to take two pills and send me more pics in the morning. Fortunately for all of us, he followed my advice and has sent me a variety of images of his labor of love for the past 3 decades.

Back in August of 1979, he innocently purchased a 1944 MB for only $800. It was pretty much all original, worn out, but in running condition.

It didn’t take long for Paul to decide to make a few upgrades, changing the engine to a V-6, purchasing a new body, and more. Then, at some point he decided the drive train needed updating, the tranny and transfercase should be swapped out, a bigger engine was needed, and the dreaded flatfender sickness had overtaken Paul.

The good news is that I believe the sickness has run it’s course, as he’s ended up with a beautiful jeep that will serve him well for years to come. Also, fortunately for Paul, he seems to encountered a disciplined form of the illness, as I don’t see 7 or 8 other flatfenders in various stages of disrepair out on the lawn :-).

You can view some additional pics of the tilting hood in this post.

Here are the specs:

Body: Acme all steel, replaced in 1980

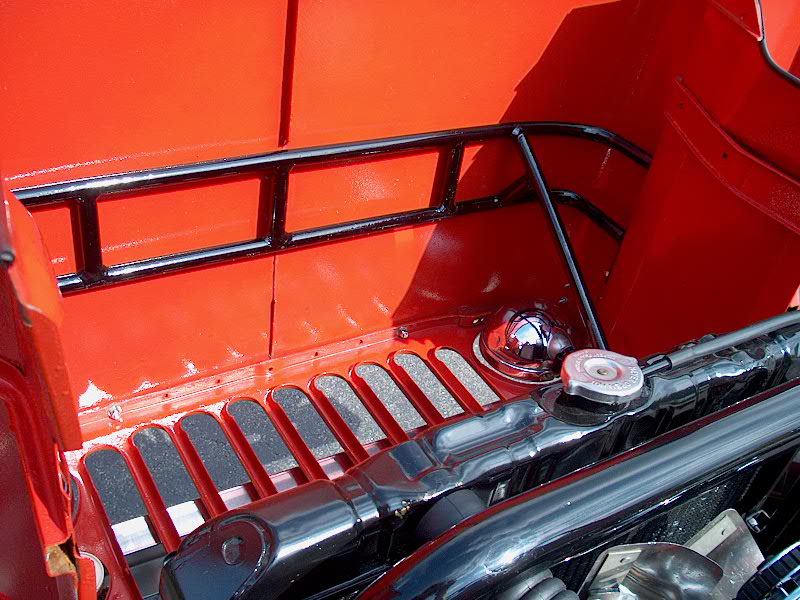

Tilt front end: all steel, tilts on a roll cage fabricated from ½” pipe

Frame: From a 2 wheel drive Jeep Dispatcher. Frame is boxed, has dual shock mounts up front. This is a much stronger frame than the original.

Roll cage: custom made, mounts to frame in 6 places. Seats mount to cage along with spare tire.

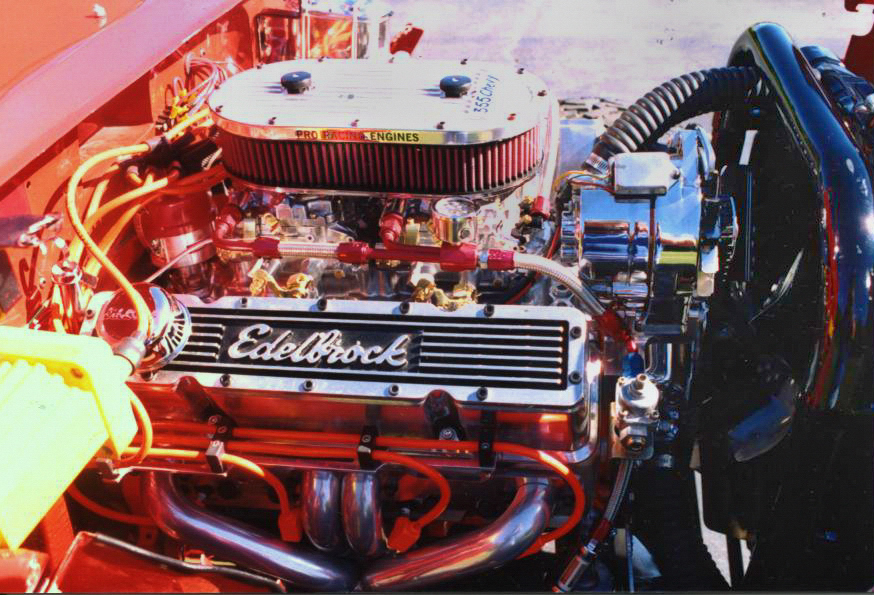

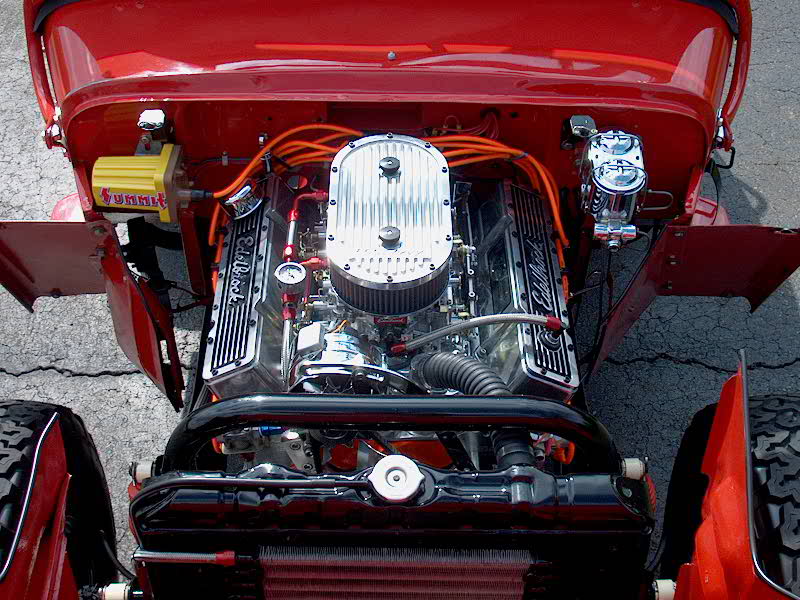

Engine: I started with the original 4 cylinder flat head, then an odd fire 225 V6, finally the Chevy V8Chevy 350, 4 bolt main, bored .030 to make 355 cubic inches. Has all Eldelbrock aftermarket equipment including internals, aluminum heads and intake, along withdual quad carbs. The combination of 400 horsepower, short headers, and small glass pack mufflers, makes the thing sounds like a demon.

Transmission: Turbo 350 with B&M shift kit and converter

Transfer Case: Dana 20, Novak brand adapter

Differentials: Early 70’s Jeep, 3:73 gears.

Steering: Chevy column out of a Chevy Caprice along with Chevy manual box. The crazy thing is that the two bolt hole spacing that held the column in the Chevy was the exact spacing needed in the Willys

Brakes: Chevy master cylinder along with swing pedal (out of a Chevy Vega), has updated 11” drums along with emergency brakes.

Seats: The tilt column makes it easier to get into the high sided bucket seats. I lowered the seats down about 4″, and about 4″ to the rear by notching the body without making it look too butchered.

Some pics of the build process:

1. View looking into garage shows MB frame on right, Dispatcher frame on left, engine and trans hanging, aftermarket body in back ground.

2. Drive train together before setting body (1989)

3. Shows how Paul cut the fenders and tied them together with the hood and grill. Note new tubing frame cross member.

4. All steel body, roll cage, bucket seats, fuel cell. Minus windshield and front end.

5. Interior shot shows dash, gauges, and tach.

6. Close up of dash

6. Close up of dash

7. Shows hand grenade transfer case shifter, B&M shifter for the 350 turbo trans, tilt column, and some dash gauges.

8. Passenger side engine Chevy 350 bored to 355. Sanderson headers, 2 Edelbrock 500cfm carbs, mount for radiator,

9. Driver’s Side engine view

10. right rear, spare tire mount to bumper and tied into roll cage, original grab handles from WWII.

11. Left side view, hood closed. (33” tires)

12. Left side view, tilt front end open.

Paul continued, “The first pic with the hood open shows the two Dzus (brand name) (learn how to pronounce Dzus) fasteners which help hold the hood down when inserted into the brackets shown in the 2nd pic. The brackets are just above the yellow ignition coil and next to the master cylinder. I also use another fastener (for a total of 4 to hold the hood) on the back side of the flat fenders. The last image shows another view of the ½” pipe as it is bolted to the top side of the flat fenders. ”

best of show as far as I’m concerned !!! share more of your pictures and any information on mockup and how you came up with the tilt front end would be appreciated. best roll i have ever seen in a willys

Rick

Thanks Rick. I experimented with my original fenders, grill, and hood. I drilled the spot welds out that hold the flat top side of the fender to the angled side. I then drilled holes through the small bottom flange on the hood, which bolted the hood to the fenders. I bolted the grill on as normal. After all of this, I attempted to tilt the front using some kind of homemade hinge. The fender, hood, and grill assembly was too weak and wobbley, so that’s where I came up with the idea of making a frame out of 1/2″ pipe, that could hold everything together, along with making a study point to pivot on the frame. I bent the pipe cold, using the built in radius on a standard pipe tripod. I can include more pictures if Dave will allow me to. -Paul-

Hi Paul,

Send whatever you’d like 🙂 I’ll see they get posted with any explanations you provide!

Paul:

thanks, more infor the better for me, am in the process of rebuilding my 48 cj2a and like alot of your build. still looking for different ideas!! how much lift do you have and what springs and shackles did you use? also what brand and size of seat if you don’t mind?

-Rick-

Rick, I used 3″ nylon spaces between the frame and the body. This allowed me to lift the body up over the engine, so I could sneak the V8 under the hood, keep the engine level, and keep from cutting a hole in the hood. I had a local shop fabricate new leaf springs with an arch about 3″ over stock. I use aftermarket shackles that probably add 2″. My tires are 33″. The look that I wanted was to be balanced (high enough to clear the tires, without doing a spring/axle flip). As far as the seats, I purchased them many years ago. They are high back, high side one piece fiberglass, good thick foam on the bottom, they came with the cut outs for the racing harnesses. I’ll have to look for the name brand. I mounted them to the roll cage by welding a steel plate on the bar, then inserting a plate under the padding of the seat, and drilled and bolted them together.

Paul:

thanks for the info. you have given me alot to think about. now, back out to the shop to finish tearing down the old jeep. I have had it for 42 years. learned to drive in it when I was 12 (now 55) so have alot of memories in it. I will probably be getting back to you in the future for more info, so will try to keep in contact somehow. just hope it doesn’t take me “decades” to finish mine, but am not in a hurry. I did save some of your pics to refer to, hope you don’t mind.

also, if you have anymore pics they would be appreciated.

-Rick-

Rick — If you are interested, I’d be happy to post some pics of your jeep and any info you have about it or plans you have for it. Sounds like a great project!

Though my parents no longer have it, the first vehicle I ever drove was my parent’s CJ-5. Sitting on dad’s lap, he worked the clutch, brake and gas while I steered around the Beverly Sand Dunes in Washington. I was around 10. Of course, every time after that, I wanted to drive it, probably to the point of annoying Dad. Maybe that’s why Dad turned over the keys to me when I hit 16.

Additionally, your comment about finding this information in the future triggers an organizational question: How best to capture, record and present this and similar information so that interested parties can find the types of modification or restoration tips they seek without having to search endlessly through old posts, especially if they don’t visit the site for the first time until 2009. This is a good challenge to solve.

– Dave

Dave:

I would be happy to post pics and information at a latter date. I’m trying to document all my moves on restoring my cj, but still in the process of teardown and deciding what I want to accomplish as to a finished product. also slow process since I am only a few hour a week restorer. So, will keep all this in mind.

also: I would love to see you work on finding modification or restoration tips easily for those looking, as this seems to be the most frustrating problem that I have found when looking for information.

thanks again, love this site, and I think you have alot to offer here. and I can’t speak highly enough of some of the builds, like Pauls. And his clean and detailed build and willingness to help and offer information is truely inspiring.

Thanks

-Rick-

Paul:

one last question> what is the OD of the tubing on the roll cage please.

thanks

-Rick-

Pingback: Reader Builds — More on Paul’s 1944 MB | eWillys

What a beautiful Jeep! What I don’t understand is why the trees are so green and where are the left over snow piles… after all, it’s only late April.

Where is Paul located? I noticed he’s from Indiana and so am I. Wouldn’t mind catching a glimpse of this ride in person.

Hello DC, I live in northwest IN near Valparaiso.

Hey Paul. I live in southern Indiana in Brown county. Kinda far away to just stop by and see your Jeep. I have a ’48 CJ3A/M38 combo.

Hey good morning is your willis Red jeep still on the market ? Thanks Rick Hebert

Hi Rickey,

Paul’s MB wasn’t on the market. He was just sharing it with readers.

– Dave