Sometime back, Dan’s grandfather had replaced the stock CJ-5 steering with a Hudson steering mechanism. However, the bell crank has seen better days, so Dan decided to upgrade to a manual saginaw. Upgrading to the manual saginaw is rare these days (see various steering upgrade options here), so it’s a nice treat to have Dan document his work for us. Thanks Dan!

Dan writes:

Here is the Jeep soon after I picked it up from my grandfathers old ranch. I had already started to disassemble it. It’s a 1955 CJ5 which he purchased in 1959. About ten years ago he told me that his best guess was that it had about 500,000 miles on it. It has seen a lot of abuse and he made many modifications to it. That’s a Hudson steering wheel and column.

As you can see in this close up, the frame is broken clean in half just in front of the divers side front wheel.

The bellcrank where he relocated it. It was just about ready to literally fall off. All the welds were broken and only one bent bolt was holding it on.

Here’s the removed bellcrank. You can see the plate that he mounted it to in order to relocate it.

A close up of the Hudson Steering wheel and column. The wheel is in pretty bad shape.

The removed Hudson steering box and column. I’m going to cut the column shaft off of the box and reuse the column shaft and tube.

The image below shows where the steering box was located. It was bolted with plates between the frame and the engine.

Here is the completed frame repair.

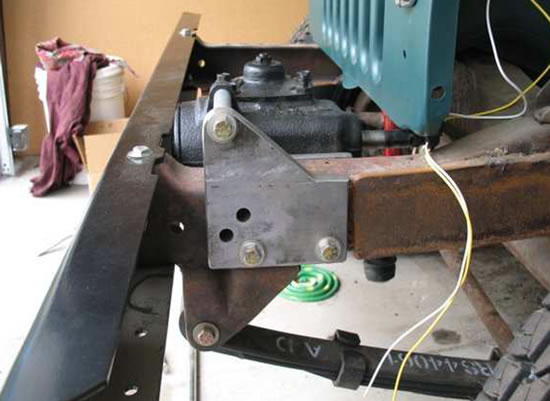

Here is the new manual Saginaw steering box installed. It is a seven turn (lock to lock) box. Most Saginaw boxes are about 4 turns lock to lock. That is why it’s not a good idea to use a power steering box as a manual steering box. It can be done by just plugging the ports for the hydraulic lines, but it makes it hard to steer. The seven turn manual box is easy to use and doesn’t put too much stress on the frame as long as you don’t go crazy with oversized tires and engine swaps.

In the below image, the adaptor plates are just bolted, but I will weld it all together before I’m done. The bad thing about the manual box is that it only mounts with three bolts. I made sure to use an extra strong mounting system to help compensate, but I’ll

never put huge tires on it. You can see the ‘modern’ tire rod and drag link arrangement. My grandfather had already made this change. I am now just having the drag link tie to the Saginaw pitman arm instead of the bellcrank.

I made a Saginaw mounting kit from some scrap steel I had lying around. The top plate is .75″ thick and the bottom plate is .5″ thick. The two smaller holes were already in the metal. I don’t think that they will effect the strength of the plates much since they are so thick. The two shouldered spacer pipes go between the frame and smaller plate. They allow me to really tighten things down without crushing the frame.The spacer pipes were made to give a tight fit with no slop. I cut down some galvanized water pipe, bored it to size, and then press fit a sleeve in them to make the inside diameter as close to bolt size as possible.

Below I am boring out the cut down water pipe.

The pipe used to sleeve the water pipe.

Here is the pipe with the sleeve pressed in. This makes for a thick wall pipe with an exact inner diameter.

A side view of the installed mounting plate. Now, I just have to weld it all up!

You can see that the tie rod is a little short. That is okay because I need an adapter there any ways. The Saginaw box and the tie rod on the pitman arm are for a mid 1980’s Oldmobile and are metric. I will machine a ‘spud’ with metric threads on one end to go into the new metric tie rod end on the pitman arm. The other end will be ‘standard’ for the original jeep tie rod threads.

Here is the center out of the old Hudson steering wheel. You can see where I cut the three wheel spokes off. I will grind them down to make room for a new adaptor plate. On the back of this is the two tines that activate the self canceling turn signals in the column tube.

The turn signal mechanism. It needs cleaned up, but it still works. If any of you have one of these and need to know what how to wiring it correctly, I found the original patent with wiring diagrams.

Just one observation. It appears that may be an M38A1 frame. Note the factory appearing shackle reversal.

Yes, I’m in agreement with you. I noticed that as well and forgot to comment on it. What I didn’t realize was that the shackle reversal was common on all M38a1s. I thought it was only on the early ones.

hmmmm, Dan, I’d be interested in that old hudson steering box with the worm, should you choose to discard it. thanks ….tom

I wondered about the shackle reversal as well. What made me think that it was indeed a CJ5 is that my grandmother said it was a CJ5, the title listed it as a 1955 CJ5, and that it matches the demo Jeep used in my reference guide. The book is called “Jeep CJ Rebuilder’s Manual” and is written by Moses Ludel. In the book he rebuilds a 1955 CJ5 for all the demonstrations. The CJ5 in the pictures looks to have the same factory shackle reversal as well. Since 1955 was the first year of the CJ5, I wonder if they left the military style shackles on it? It would be really interesting to find out for sure. I’ve been looking around for any other identifiers that may give a clue. The serial number is 57548 19242 which I believe places it as a 1955 CJ5, but that’s not to say the frame was ever swapped out. I know that the engine is out of a 1960’s Jeep, and the hubs are like no others I’ve seen (the Thor Lectro Matics shown elsewhere on the website).

Tom,

I was planning on cutting the shaft about two inches above the gearbox. Would you still be interested in the steering box and worm?

Interesting … Maybe that’s what I was thinking about when I mentioned that there was limited production on the shackle reversal. I did some prelim searches, but didn’t find any confirmations yet. I’ll look a bit more after I get done updating the website a little later tonight (working on my console right now).

= Dave

Interesting indeed… I’ve never heard of a CJ with a factory shackle reversal, but that doesn’t mean it didn’t happen. The body appears to be most definitely CJ-5…

I’m certain that is a CJ-5 or possibly a militarized cj known as the M-606, though I doubt it. 1/3 of the frame for a M38A1 is boxed from the front and upon other key stress points along where the spring mounts are. Also, you would never see a “jeep” stamp on the driver-side of the tub. cause technically, it wasn’t marketed as Jeep “per se’ for the Military. Also, notice the Mfg tag is on the engine bay side of firewall (driver-side). The Mfg tag, on all M38A1 were placed along the top slop of the passenger side rear wheel well. With all the mods that were done to these old girls back in the day, I would suspect the suspension was a home-brew shackle reversal.

yes Dan, I think I would still be interested in the box, are the worm shafts readily available? I’m interested in the box because you get a better turning ratio, “psuedo power steering” as a bolt on without the unecessary mod or drilling . let me know. also, save the bolts that mount the box to the frame with it too please.

Well, if I learn more about any CJ-5 reversals, I’ll report it here.

– Dave

Tom,

Shoot me an email. dvanwormer@gmail.com

The M-606 was a militarized 3B. No doubt that this tub is definitely CJ-5…No argument there. I was only pointing out the factory appearing shackle reversal known only to an M38A1 on this frame. If there were CJ’s (any of them) from the factory with a shackle reversal I’ve not seen or heard of one.

Pingback: Builds: Dan’s Grandfather’s CJ-5 Part II | eWillys

Pingback: Dan’s Grandfather Transports 2 Horses | eWillys

The very first early cj5’s ’55 and some early ’56’s did in fact have a shackle reversal like the M38A1’s So your frame is probably stock. Look on ECJ5 site for more early cj5 info.

Hi Windy,

Thanks for the info. We’ll have to wait until the ECJ5 site gets back online, but I’ll dig into it as soon as I can.

– Dave

Pingback: Mods – Steering upgrade options for Early Jeeps | eWillys