Brian sent me some updated pictures of his CJ-3B project. He just finished reversing the springs in the front. As a part of that reversal, he had to replace the front of the frame. After conquering this task, he turned his attention to the rear differential, only to discover a big problem (which he'll update all of us about as he progresses through the issue).

Brian explains more below about his spring reversal experience below ….

"I wanted to do a spring reversal so I started by getting some universal after market parts to make things a little easier. Then I bought a early Cj5 frame for the front 8 inches then sold off a chrome bumper and ring and pinion at a small profit.

Here's what I did to lengthen the frame.

I cut a block to use as an template to cut off the front of the 3b frame. (Stan H. — from the Wandering Willys Jeep Club — always said to cut at a 45 degree angle though the frame.) I did the same with the pieces to be added. They lined up really nice.

I only have a 110v welder so I had my local fab shop out to weld up the front.

They also fabbed up a 3/16 "U" channel to run on the in side frame rails to box it in. I added about 5 inches to the front.

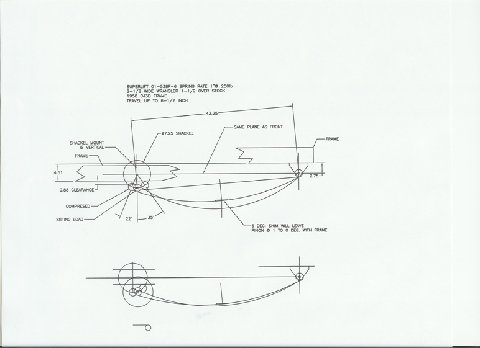

I never had done any work an a spring reversal and only had seen 2 in person. I could not find a kit for early CJ's, so I studied all I could find on the Net. I did a Auto-Cad drawing of what I wanted to do. I contacted Mountain Off-Road Enterprises. They were quite open to talk to me and happily reviewed my drawing. They concurred with most of the measurements on the drawing. My big question was… At what angle should the shackle be at when it is at rest? They told me 5 degrees. In my mock-up I followed their advice by drawing them at 5 degrees then made some changes to the build. I dropped the front mount 2-1/2 inches and put the pivot point for the shackle at the bottom of the frame. This gave my pinion a better angle.

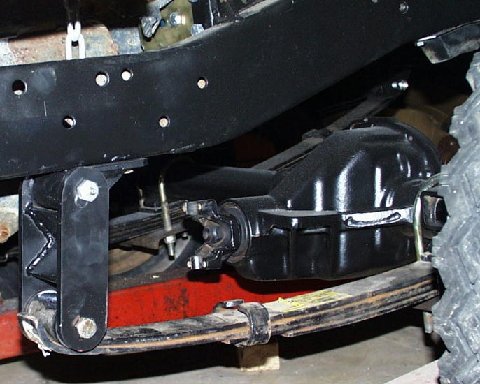

Next I had to find were the rear spring eye would be under load. So I loaded the engine and trans back on the frame. Cut some blocks to act like the shackle and greased them up to make the spring eye slide. This worked well. I used a level and marked the frame. Then used some good old math to find 5 degrees. Drilled the frame and bolted every thing up. Note the nice angle of the pinion

Over all the frame rails came out good and strong here is the front

To keep my approach angle close to stock I will have to run "33s" or bigger. I am getting about 2-1/2 of lift from the new springs and plan to lift the body some. I am running 5:38 rear ends I can go to taller tires. The vertical spring travel is 6-1/2 inches that should let my tires travel 14 to 22 inches we will see.

I now working on the power steering and the rear springs

Looks nice, I noticed you mentioned Stan H. I jeeped with Stan and the WWJC for years. I have a 3A and have been working on ity for teh last 18 years. Currently it has a 283, TH350 , 44 rear with a floater kit. 30 front. Lockers and discs. I just found this site, I will post a pic when I figure out how.

Send me your pics and a few notes and I will post it for you. You can email me info at d@ewillys.com.

Both I and Brian belonged to the WWJC, and both knew Stan and others from WWJC, but I left for college and stopped jeeping (1986) around the time Brian started (Brian and I met through a craigslist deal last winter).

– Dave

The Jeep I bought was owned by Jim Carter(original member of the WWJC) the race name was Pittle Power, Skip Baird helped me with my first swap with a V-6 and a top loader, Al Hamilton and I became very close infact I still have one of his pups Mandy she is a very stubborn German Shorthair. I will send you some pics